Our Services

Expert solutions and comprehensive audits tailored to your industry needs.

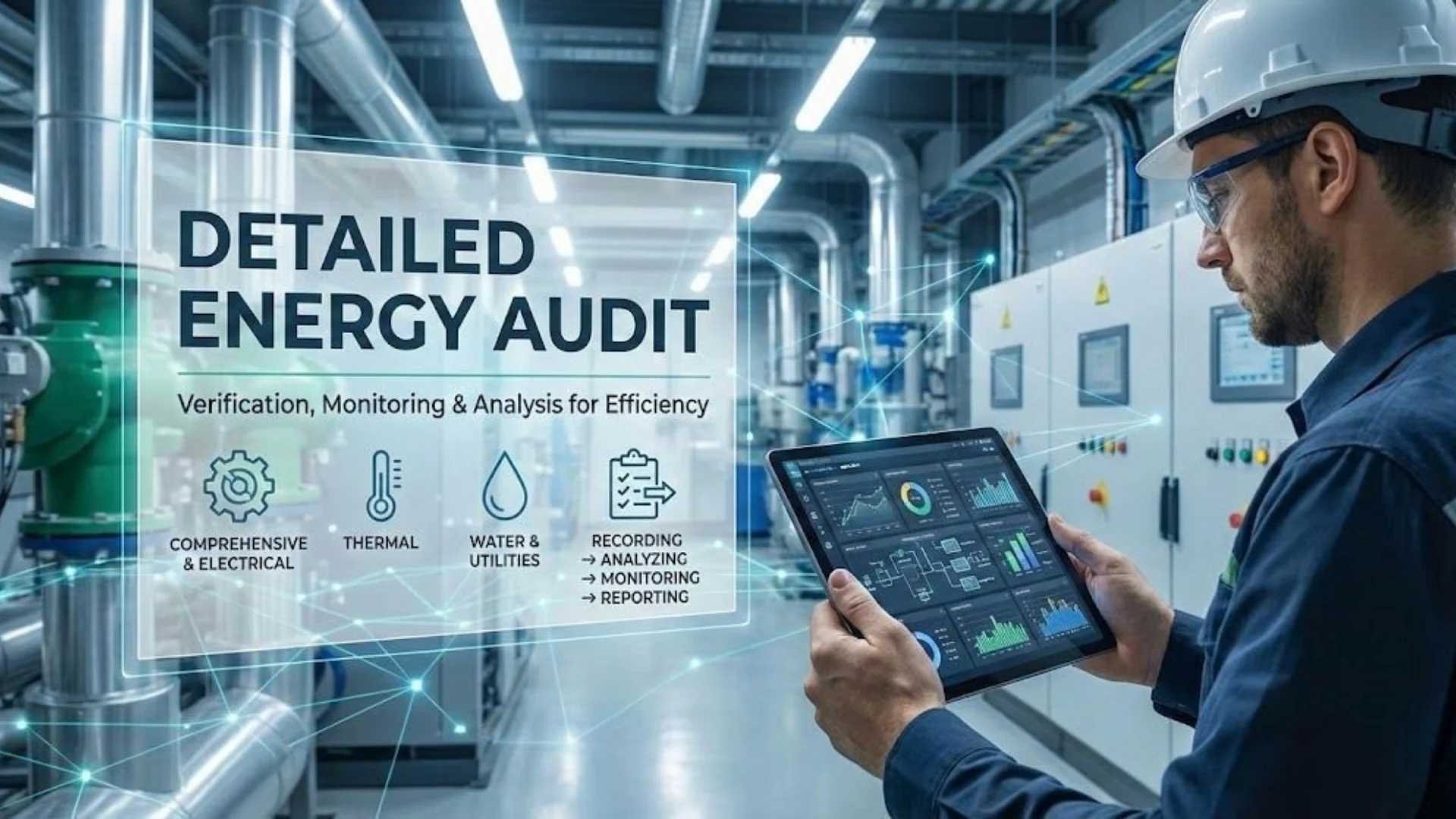

Detailed Energy Audit

Energy Audit is defined as “the verification, monitoring and analysis of use of energy including submission of technical report containing recommendations for improving energy efficiency with cost benefit analysis and an action plan to reduce energy consumption”. It builds on the principle "you can't manage what you don't measure". It essentially combines the principles of energy use and statistics.

Energy Conservation

Energy conservation is the effort made to reduce the consumption of energy by using less of an energy service. This can be achieved either by using energy more efficiently (using less energy for a constant service) or by reducing the amount of service used (for example, by driving less).

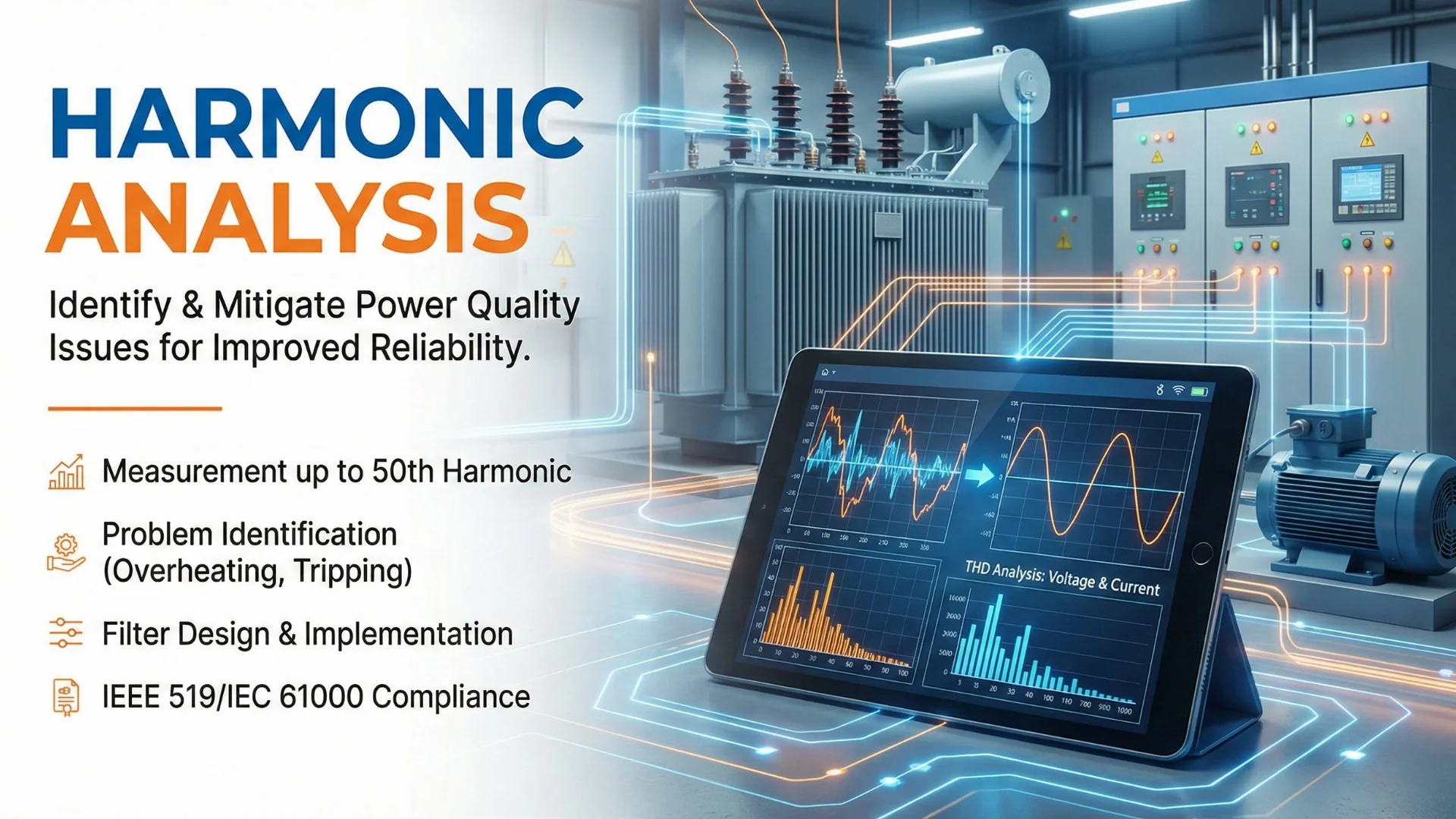

Harmonic Analysis

Harmonic analysis is a technique used to study and analyze the harmonic components in a periodic waveform or signal. The main use of harmonic analysis in electrical engineering is to examine the existence and properties of harmonics in electrical power systems. Harmonic voltage or current waveform frequencies are integer multiples of the fundamental frequency. However, due to non-linear loads, such as power electronics, variable speed drives, and certain types of lighting, harmonic currents and voltages can be introduced into the system.

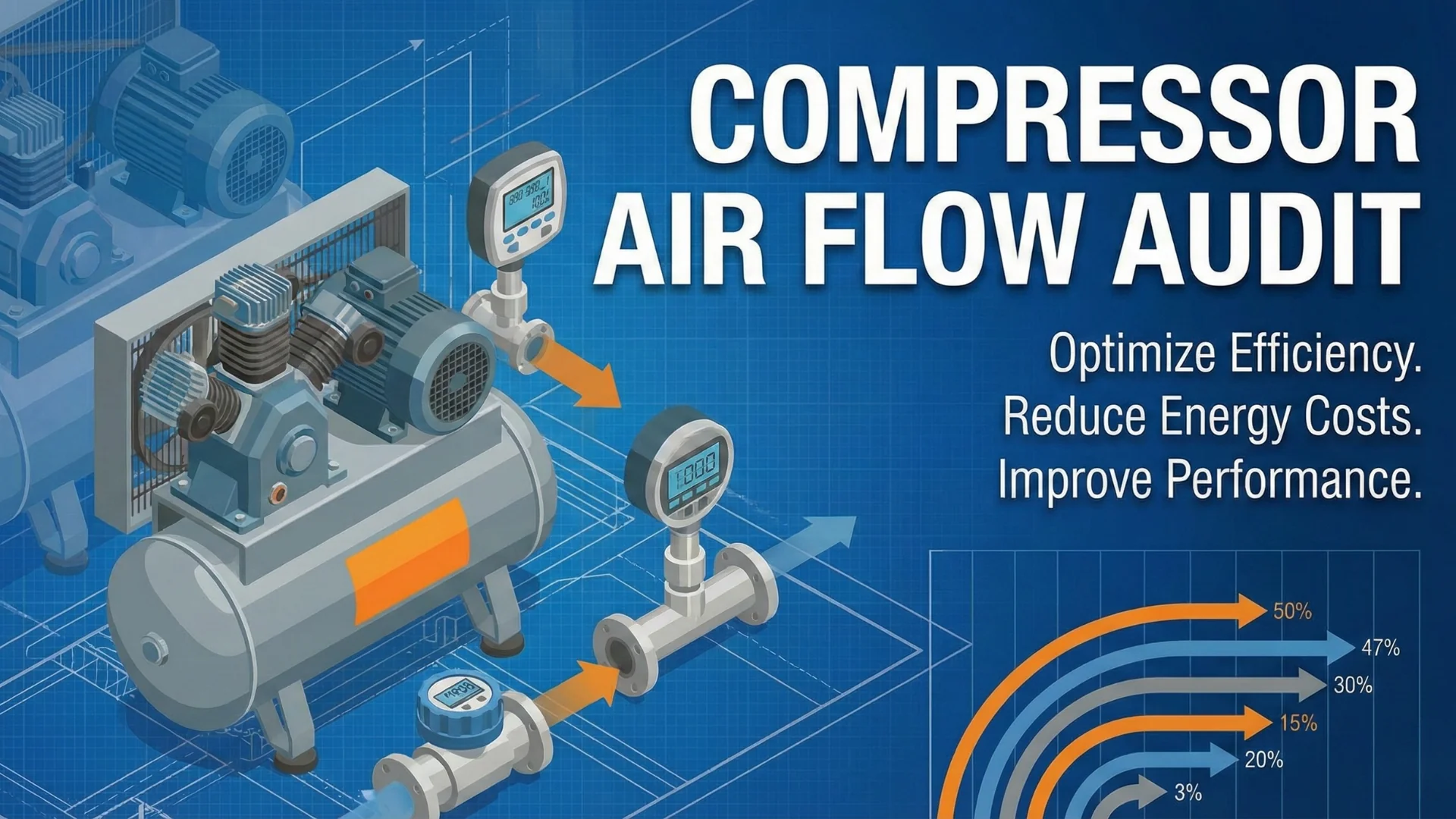

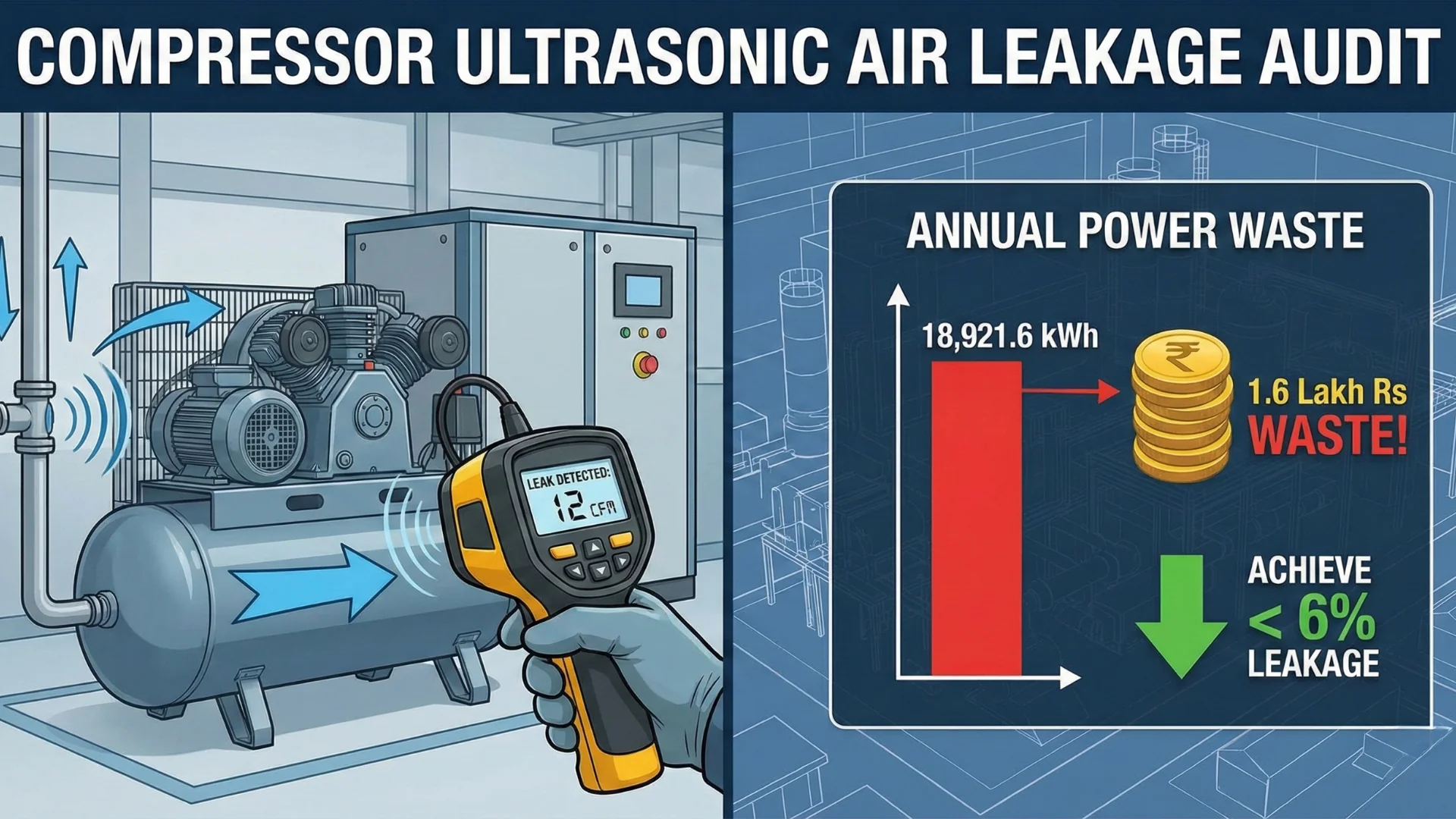

Compressor Air Flow Audit

A compressed air audit effectively identifies inefficiencies, reduces energy costs, and improves system performance. Many industrial air compressors operate inefficiently due to leaks, artificial demand, and incorrect air pressure requirements, unnecessarily increasing cost per kWh.

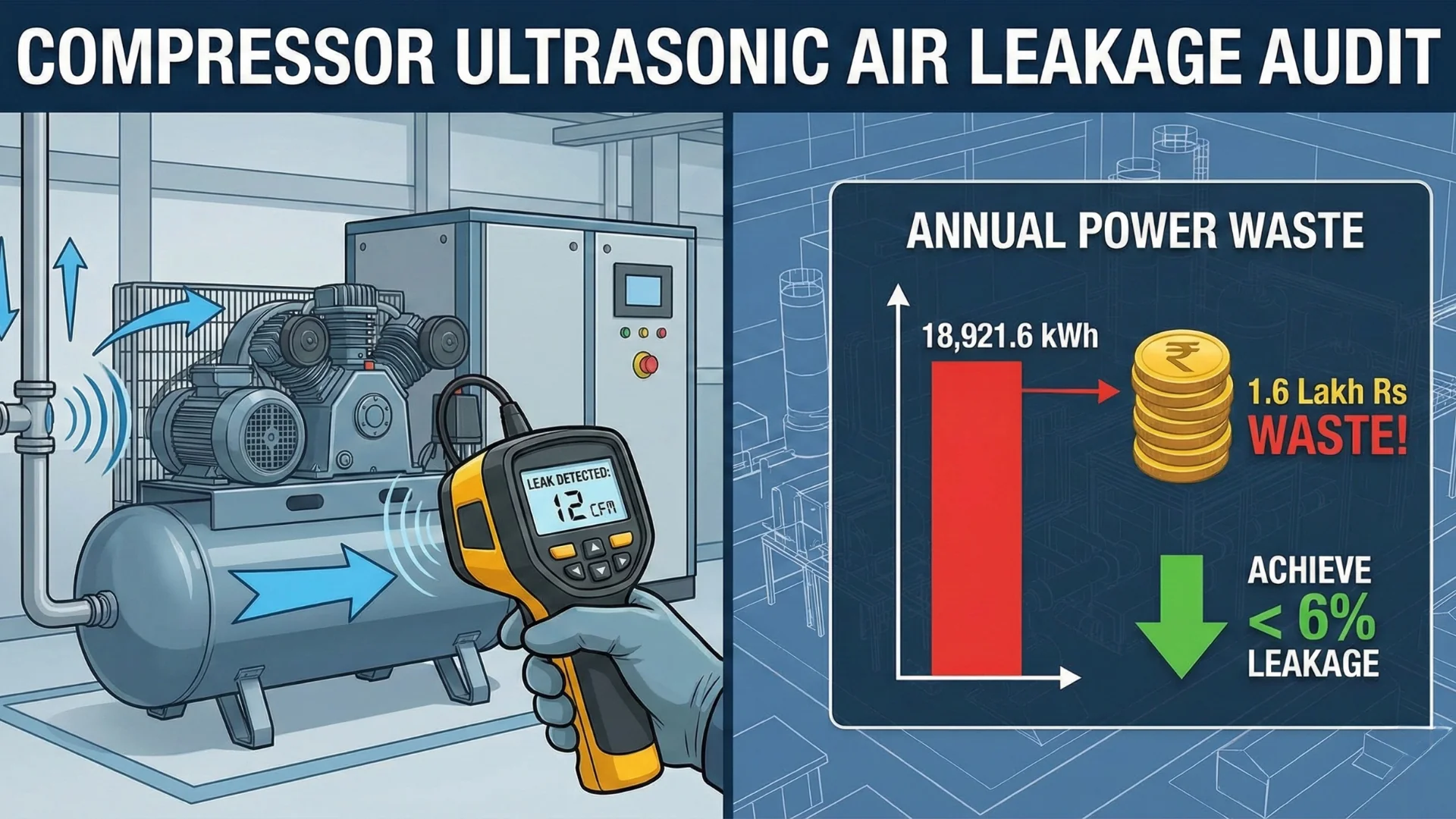

Compressor Ultrasonic Air Leakage Audit

We provide the Compressed Air Leakage Audit service and Compressed Flow Audit Service. Have a look!

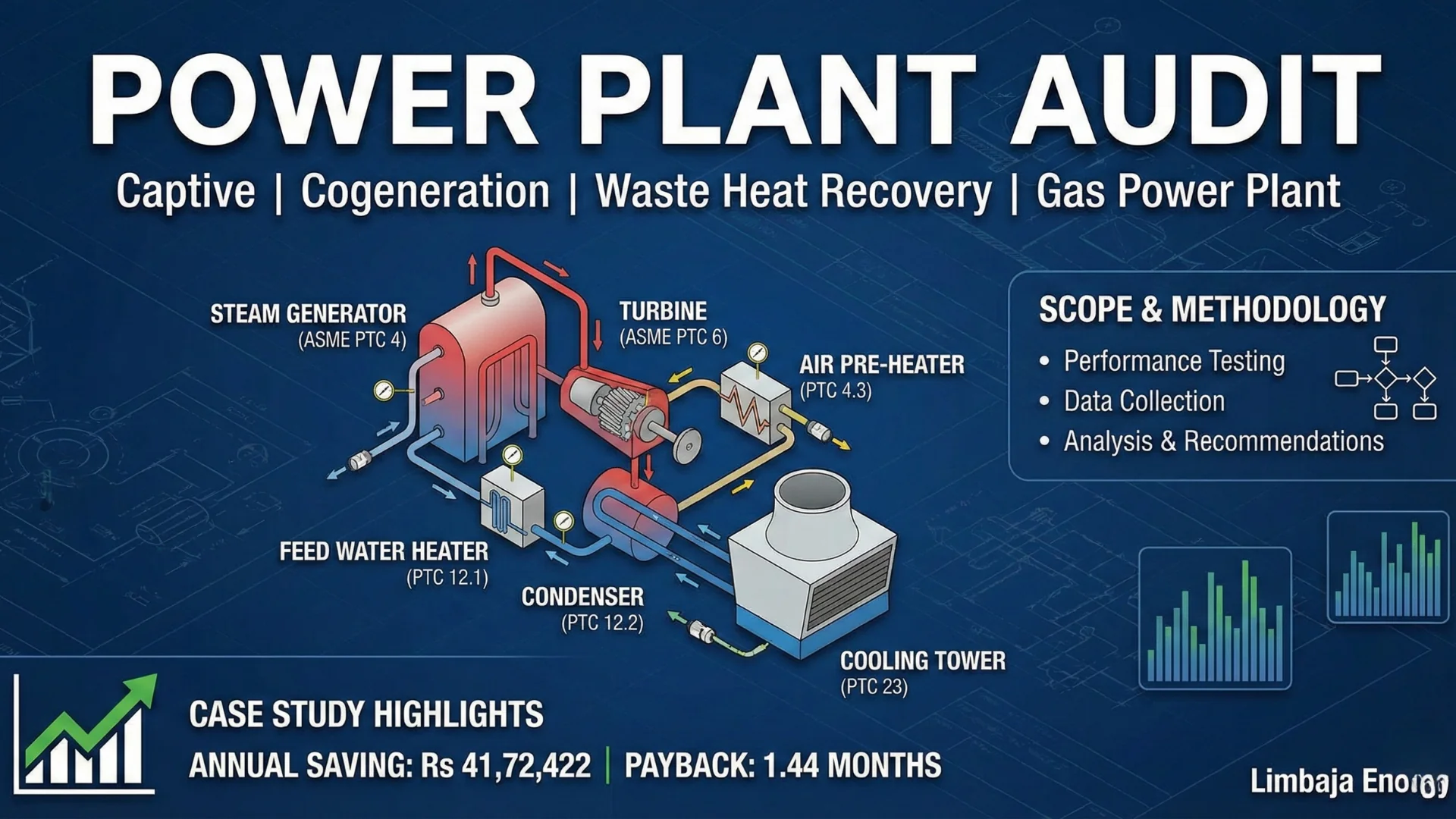

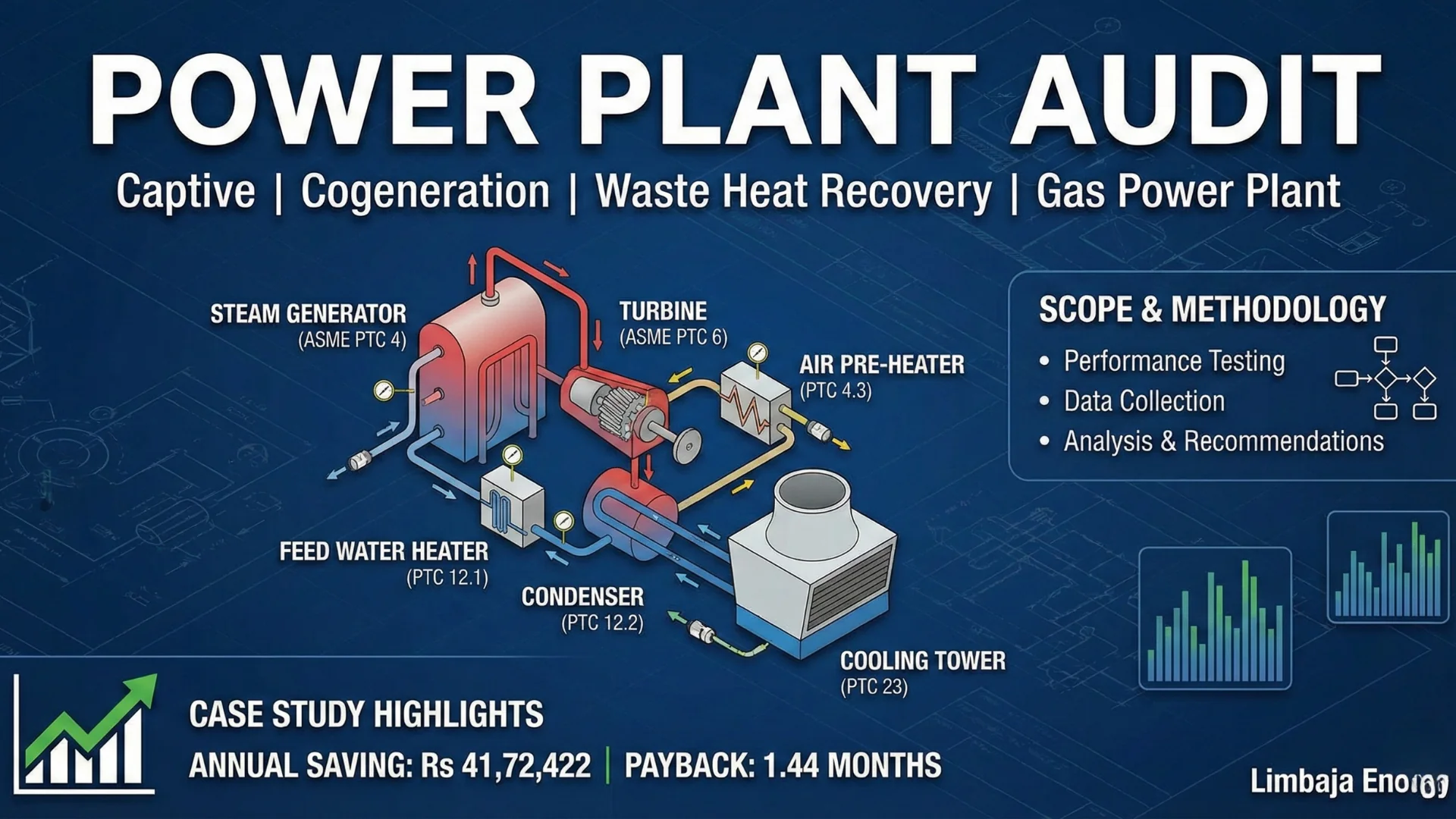

Power Plant Audit

Performance testing of Captive, Cogen, Waste Heat Recovery, and Gas Power Plants in accordance with respective ASME PTC Codes.

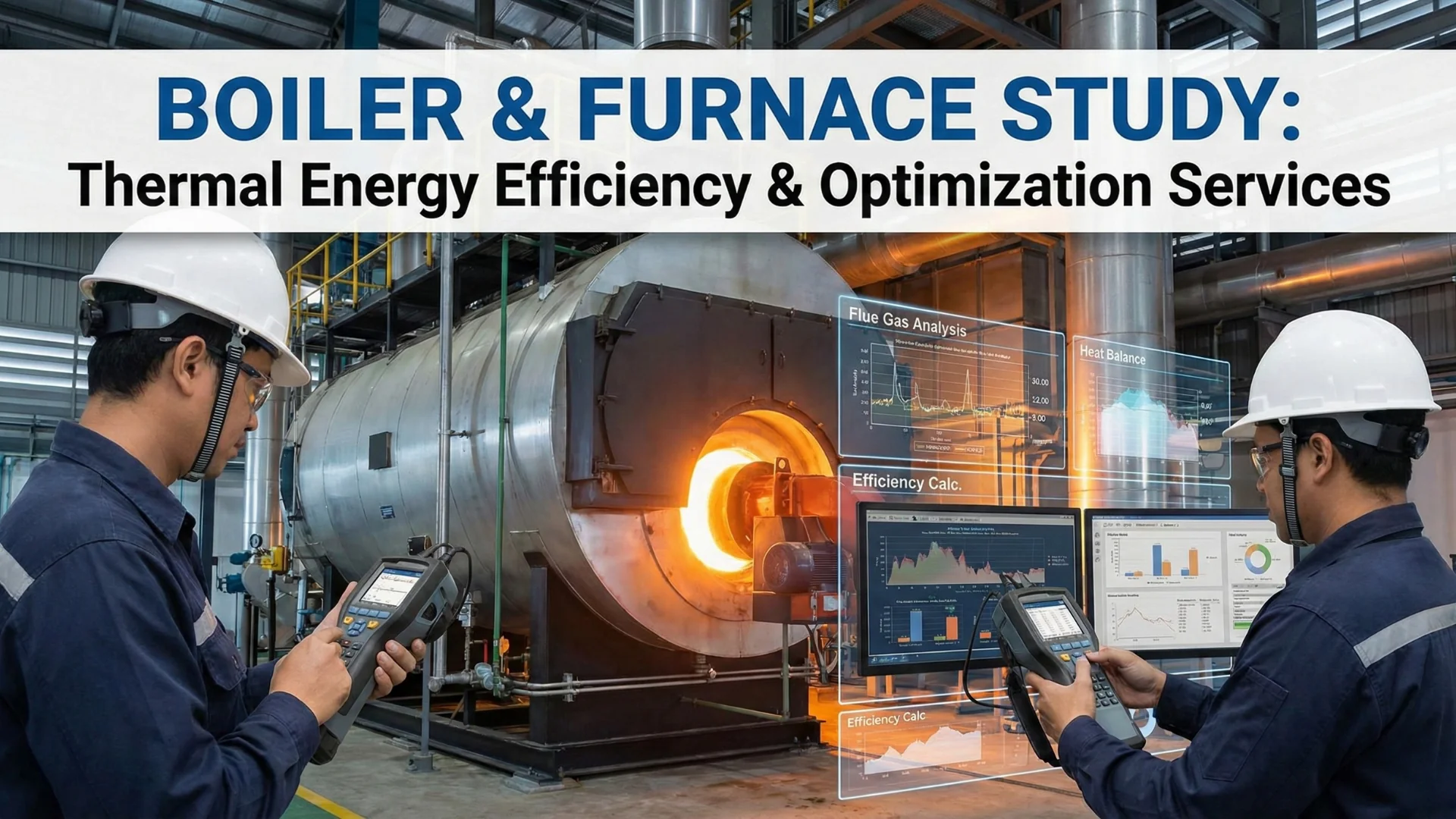

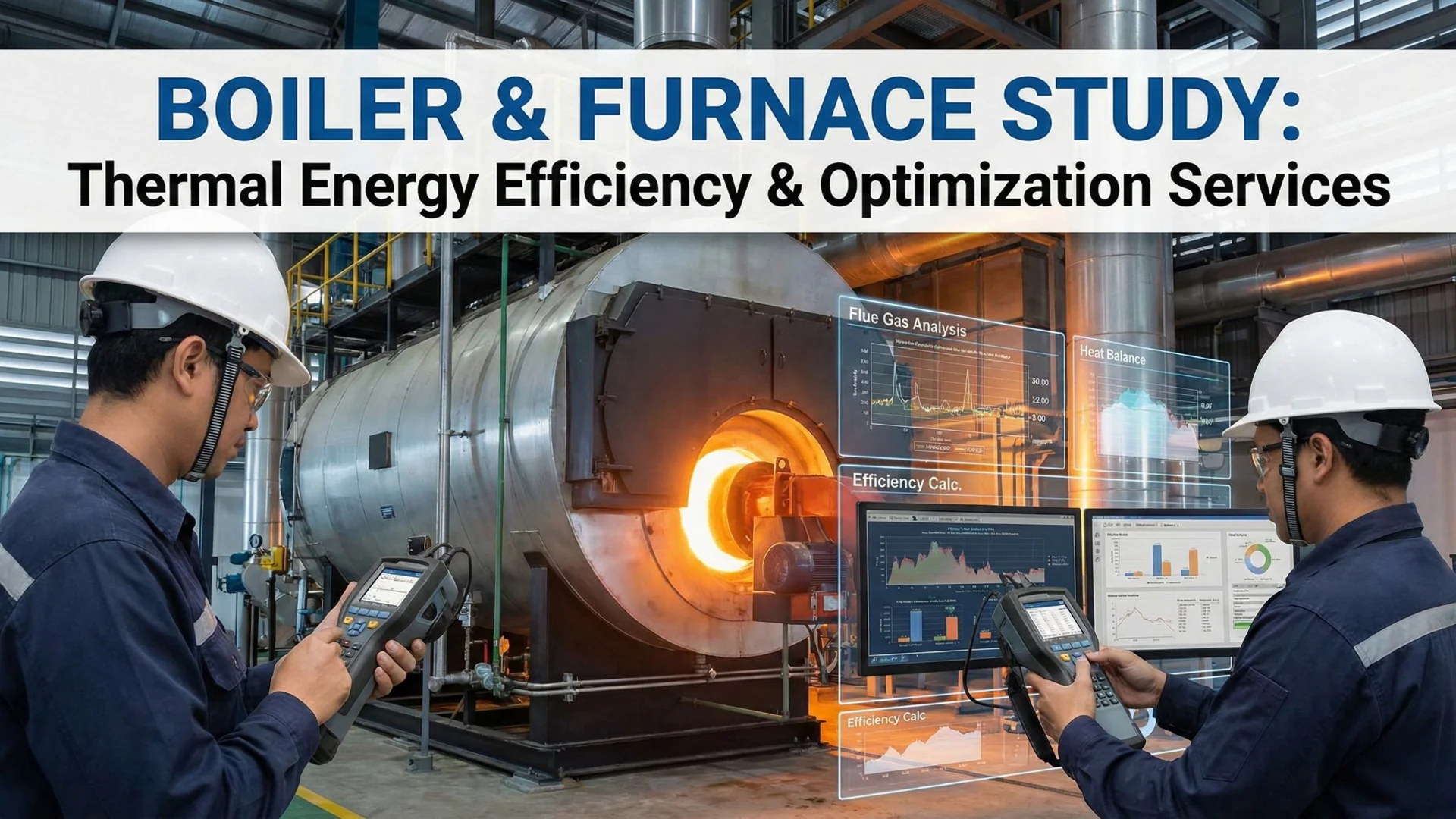

Boiler & Furnace Study

Studies are undertaken to determine efficiencies of generation, distribution & Utilisation of thermal energies. Boiler efficiency tests are carried out to determine steam generation to fuel ratio.

Flow Measurement

Accurate flow measurements are critical to the calculation of Utility or process control applications. Flow Measurement is also useful for monitoring & troubleshooting internal processes at various points. measures the flow of virtually any fluid, be it liquid, gas or steam, regardless of the flow direction (bi-directional) and over an extremely wide measuring range. Due to its practical advantages, external flow measurement with clamp-on ultrasonic transducers has become a standard measuring technique in a broad range of industries and applications. This flowmeter can be installed in just minutes without needing to shut down, thus avoiding costly downtime. This ultrasonic technology works with gases at high or low pressure in pipes made of metal and most other materials.

Process Heat Mass Balance

Heat and mass balance is a critical aspect of process engineering, used extensively in the design and analysis of process plants. These calculations ensure that the energy and material inputs and outputs in a system are accurately accounted for, helping to optimise efficiency, safety, and cost-effectiveness in industrial operations.

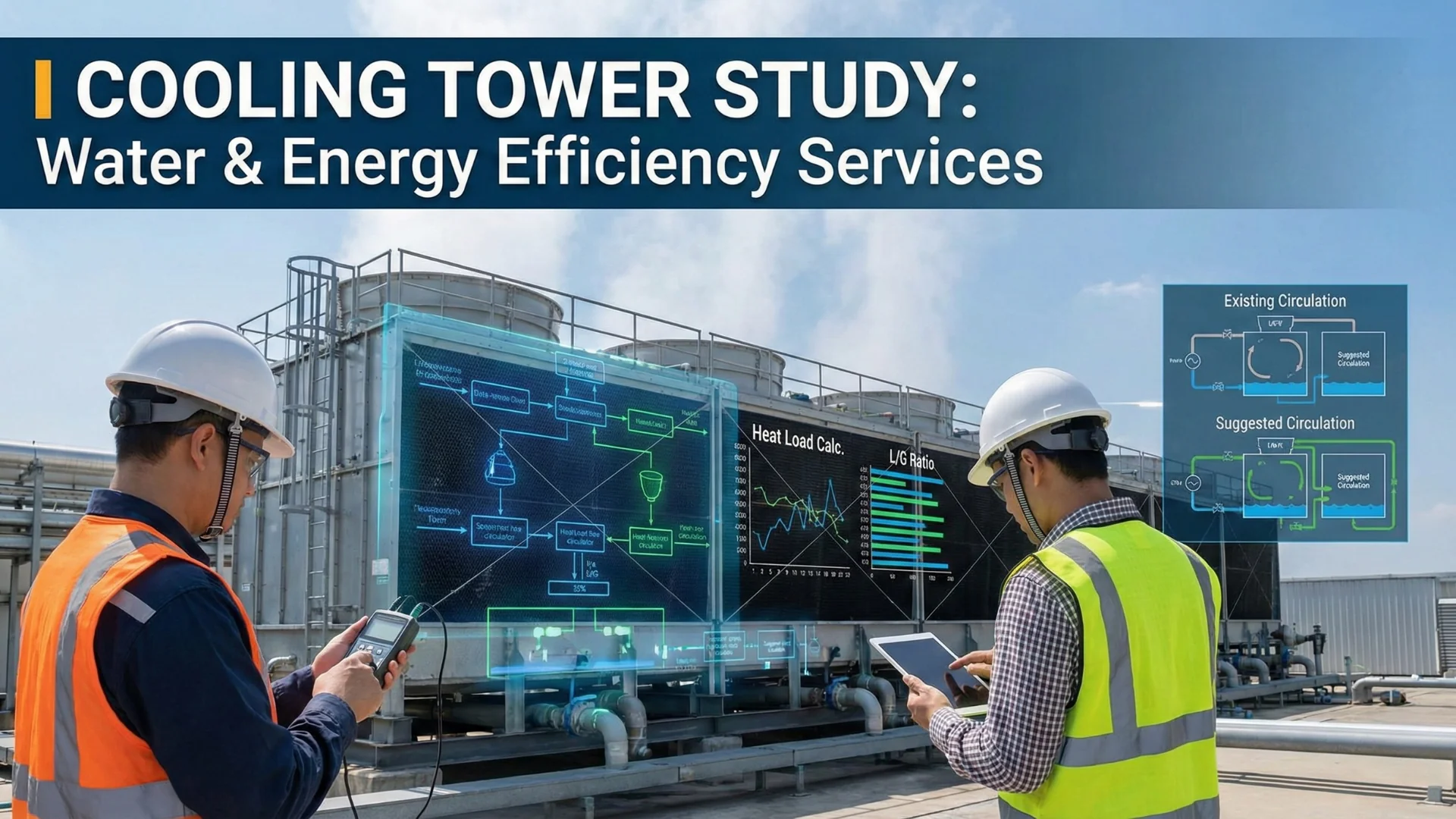

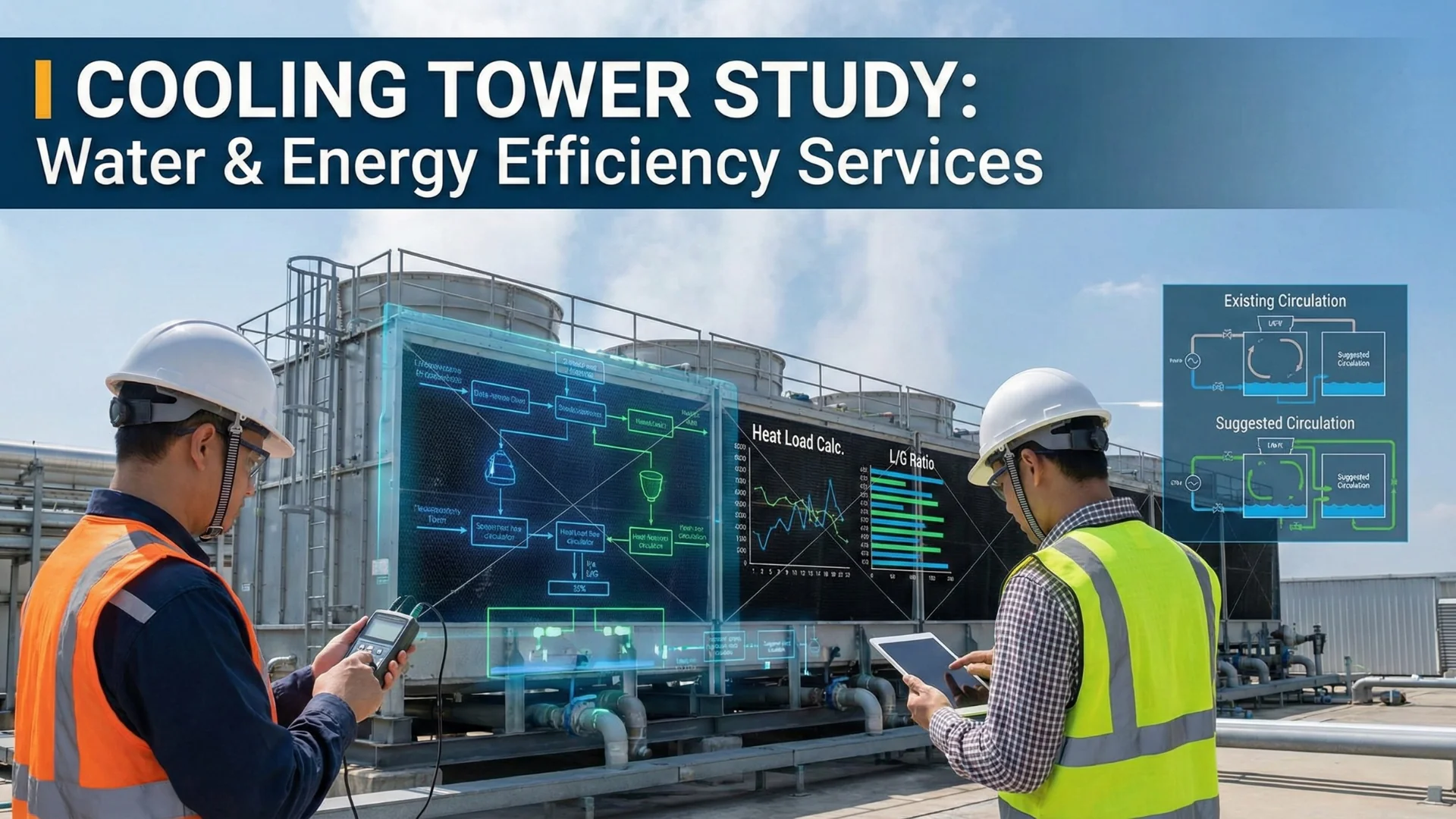

Cooling Tower Study

Cooling towers represent largest reuse of water in industrial and commercial applications. Cooling towers offers the means to remove heat from air conditioning systems and industrial processes generating excess heat. Cooling towers are normally designed for maximum process load and worst ambient conditions. Optimizing operation and effective maintenance of cooling towers systems offer facility and process managers significant savings in energy and water consumption. As result saving potential of about 20-25% can be achieved by optimizing excess capacities of pumps and fans catering to under loaded process.

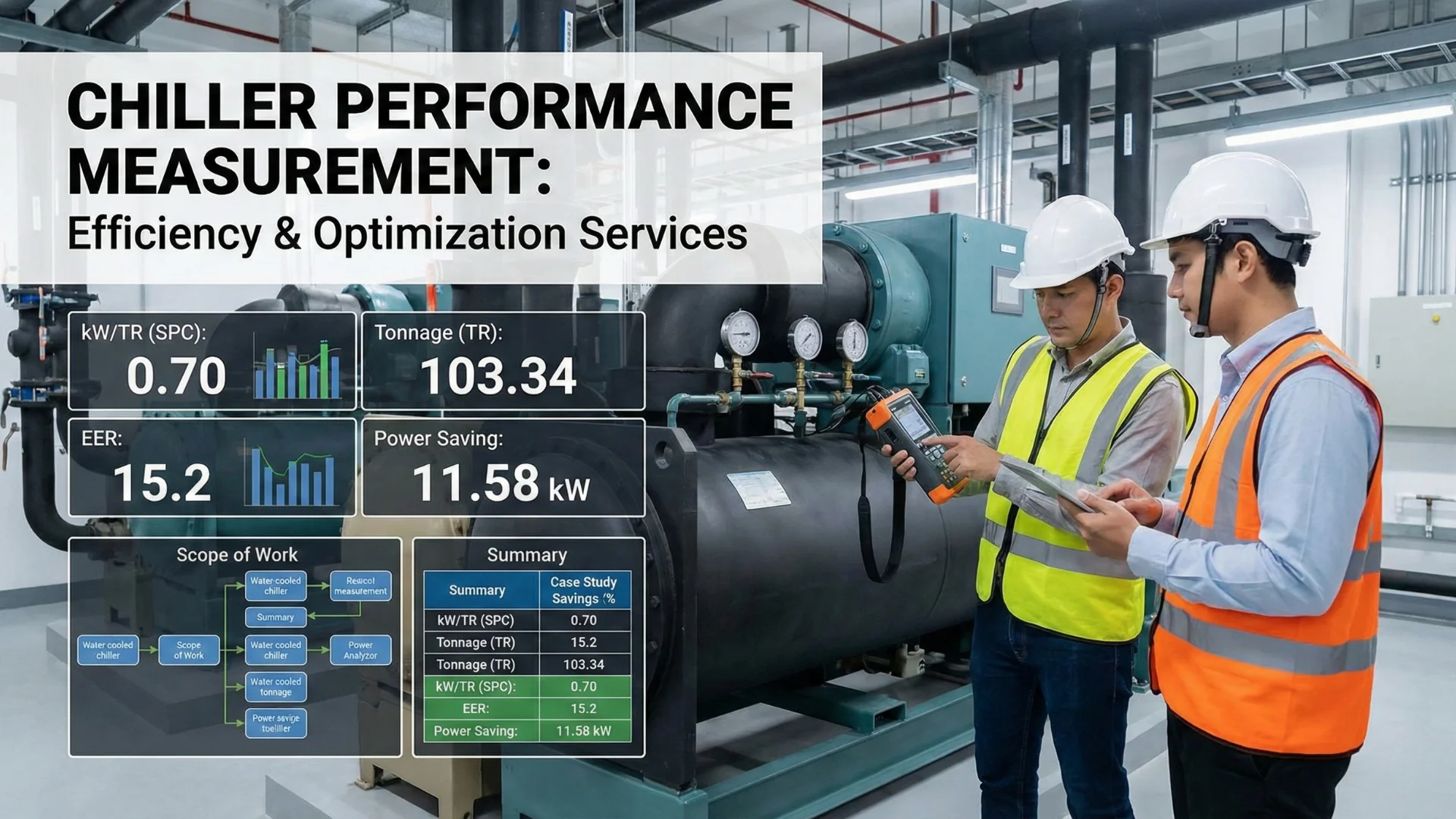

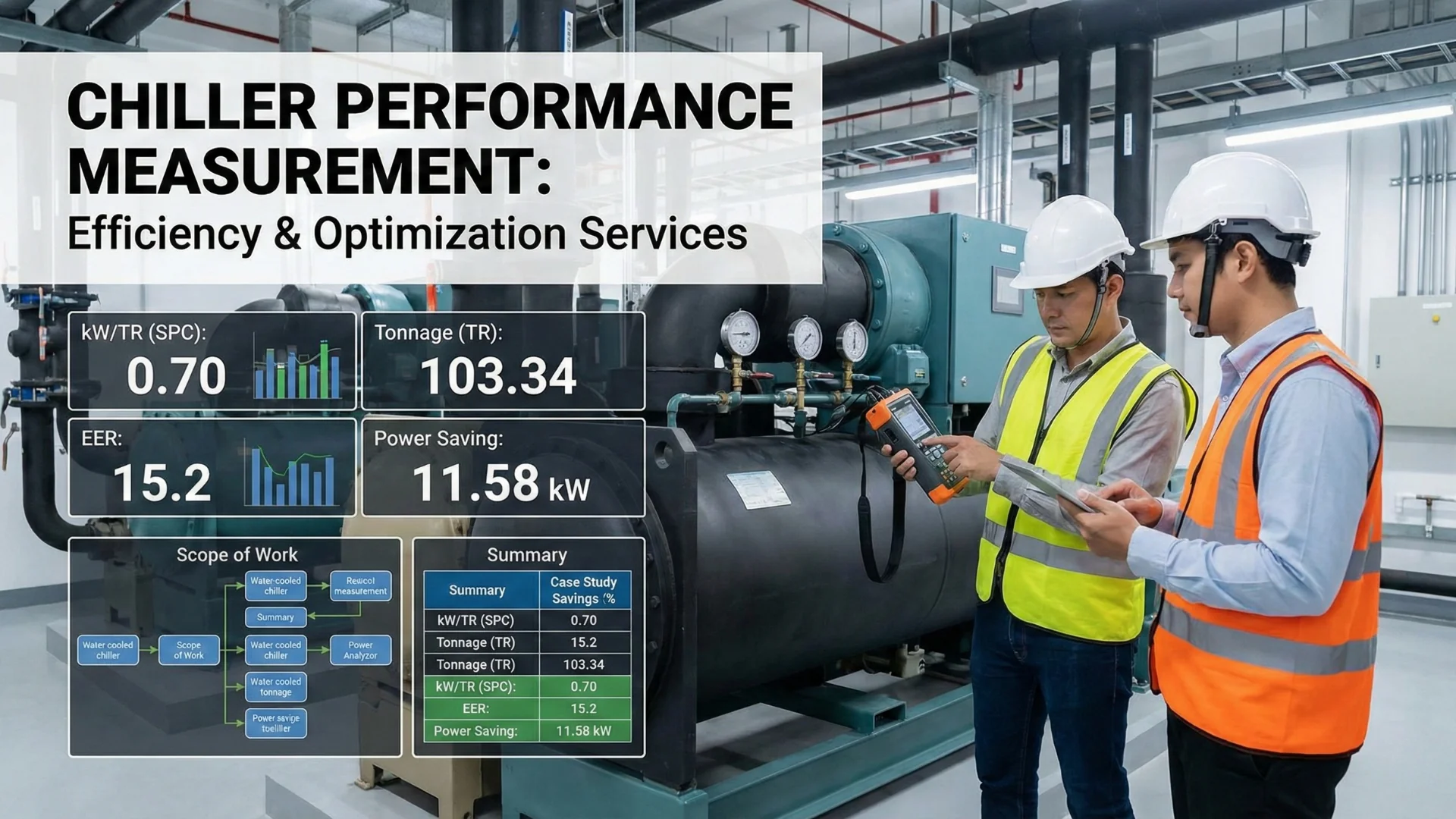

Chiller Performance Measurement

The performance assessment of the chiller plant involves calculation of cooling duty delivered by the system and measurement of power consumed by the unit. The Specific Power Consumption (SPC - kW/TR) and Energy Efficiency Ratio (EER) are the effective measures for comparing the electrical energy input to cooling duty delivered by the system. The study involves measuring various parameters such as flow rate, temperature and power in the both chilled water and refrigeration side of the chiller system.

Lighting System

Lighting is an essential service in all the industries. The power consumption by the industrial lighting varies between 2 to 10% of the total power depending on the type of industry. Innovation and continuous improvement in the field of lighting, has given rise to tremendous energy saving opportunities in this area.

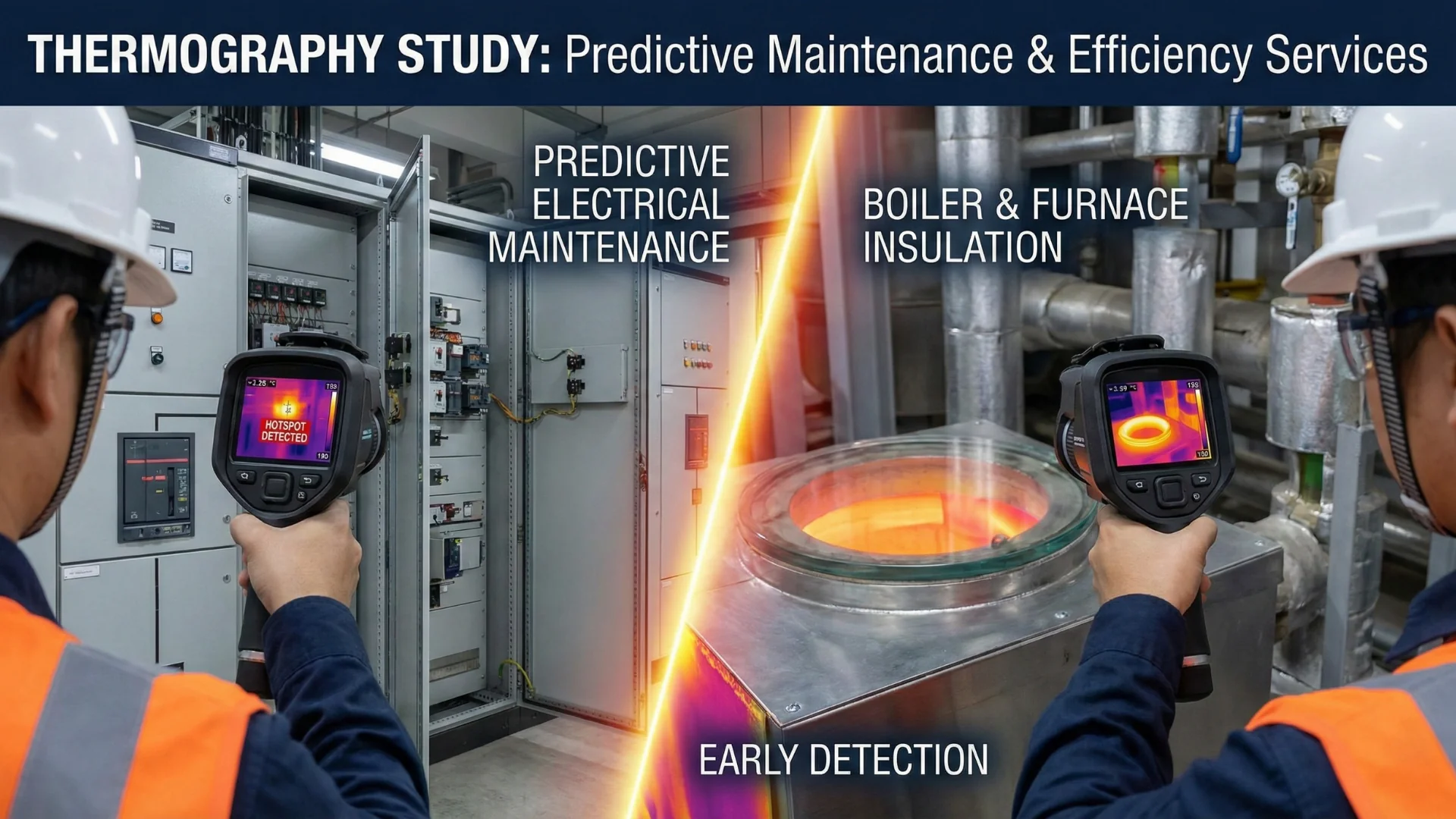

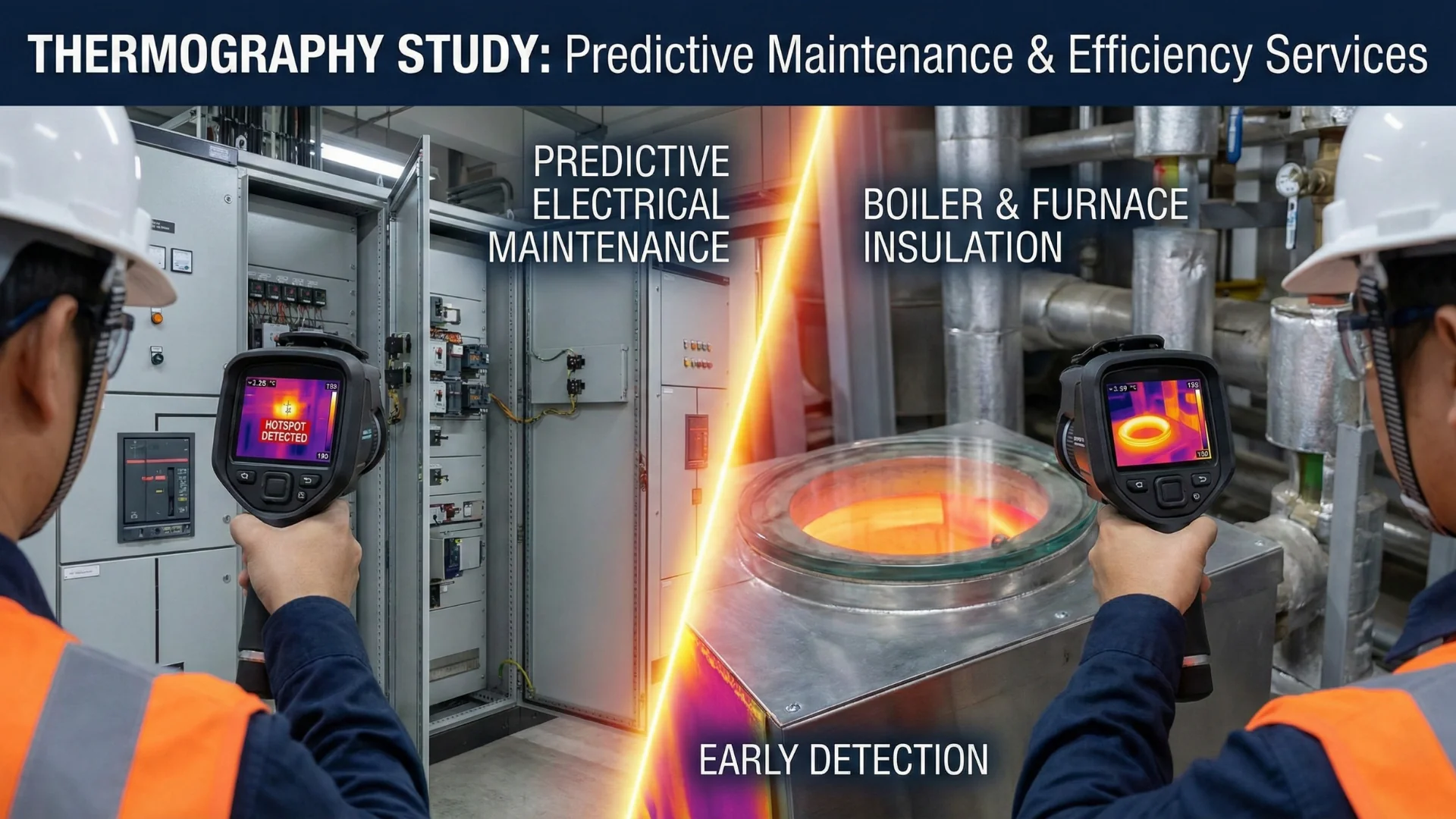

Thermography Study

Thermography Study is use for Predictive type maintenance. Many problems begin with an increase in temperature, and the IR camera allows for early detection of these potential problems that might otherwise go unnoticed. Thermal imaging allows inspections to be conducted more efficiently, without disrupting any surfaces, equipment, or barriers.

Steam Trap Audit

A steam trap is a mechanical valve that separates condensate from steam for a return trip to the boiler. Many steam traps underperform by plugging or sticking, leading to inefficient separation of water from steam. Optimized steam traps can reduce energy costs by 10% to 15%. In a steam strap study,

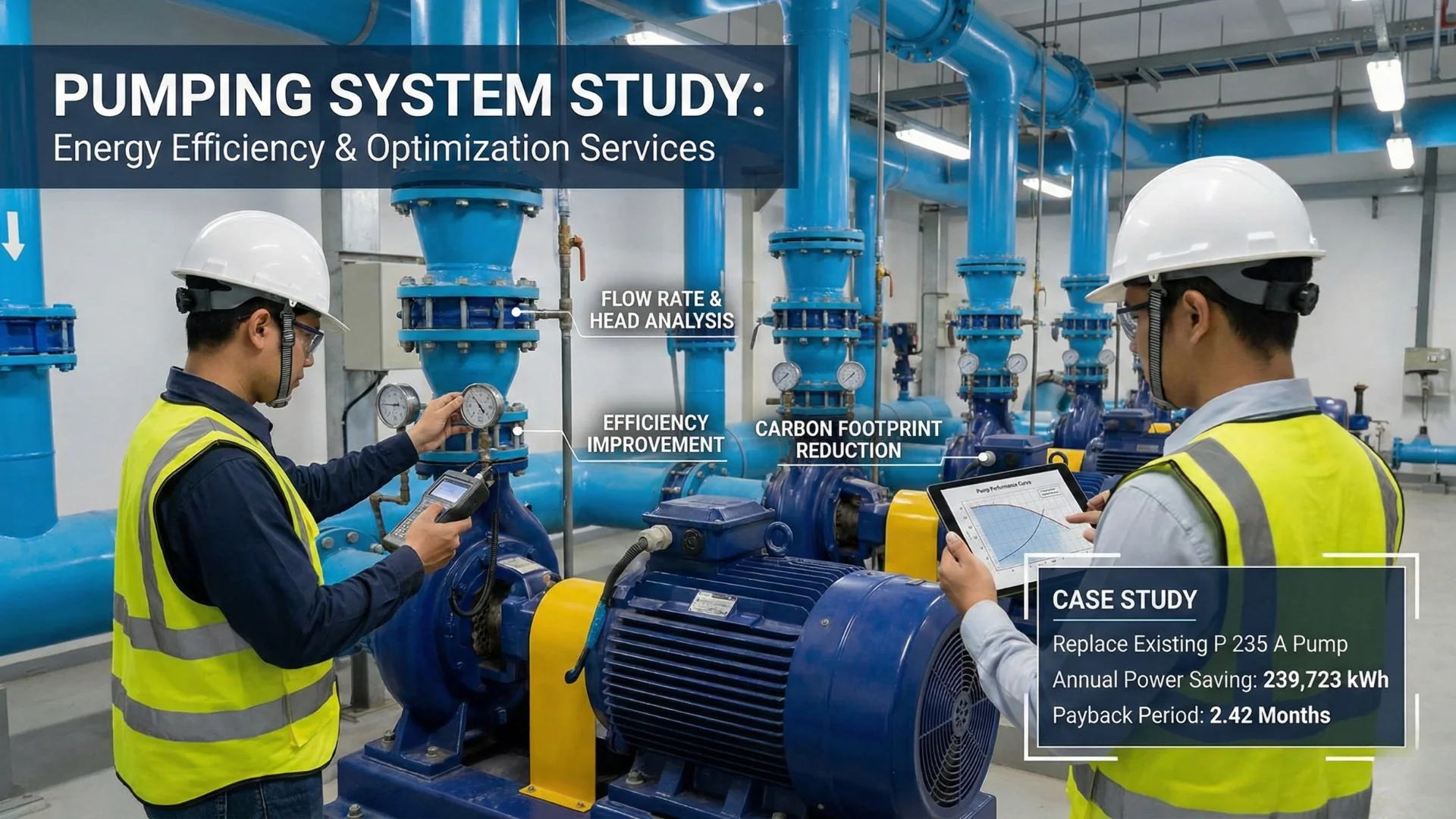

Pumping System Study

All pumps have a characteristic or performance curve that describes the flow rate produced at net or total head. Pump specifications relating head and flow rate correlate to those found on its characteristic curve.

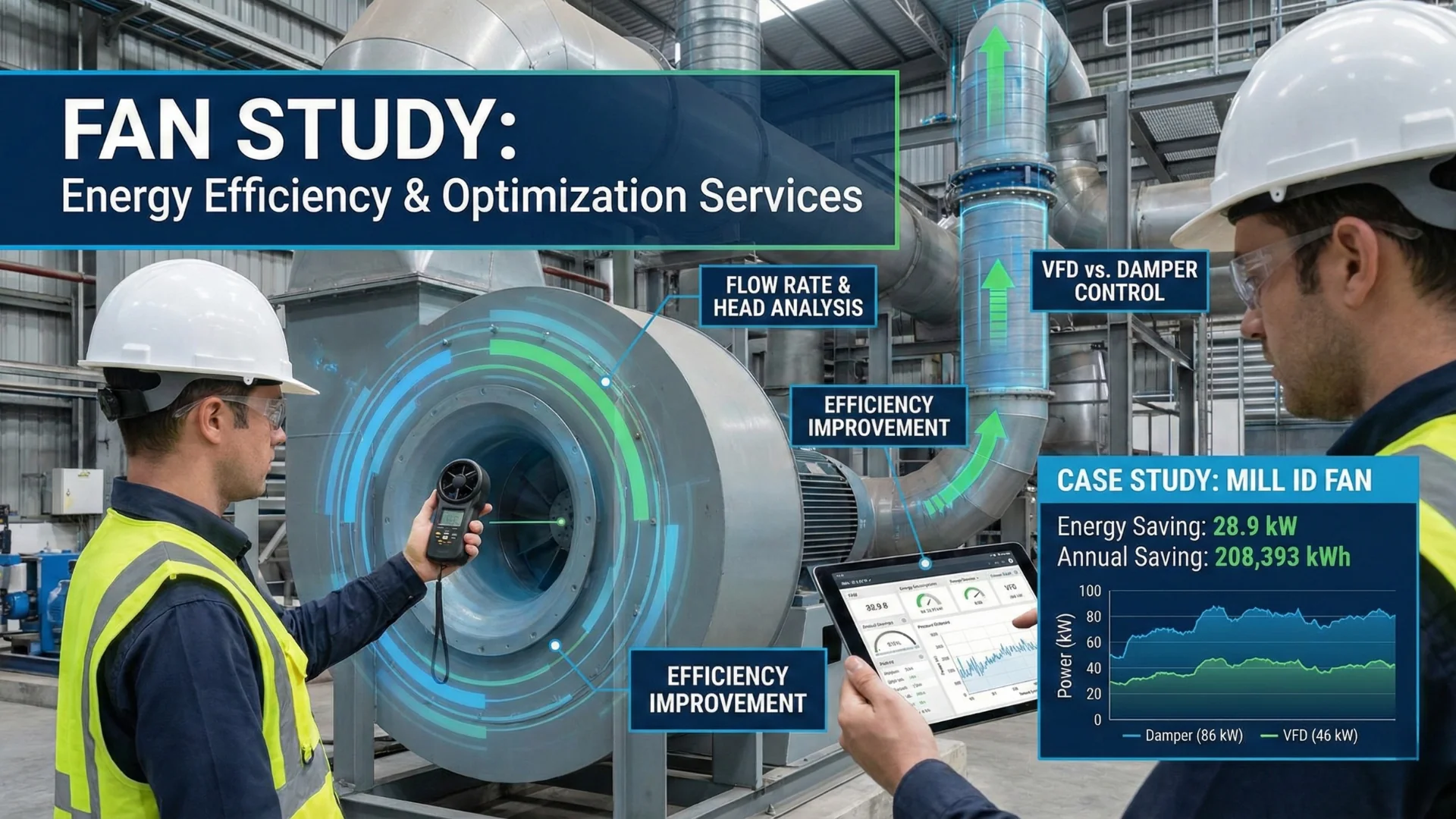

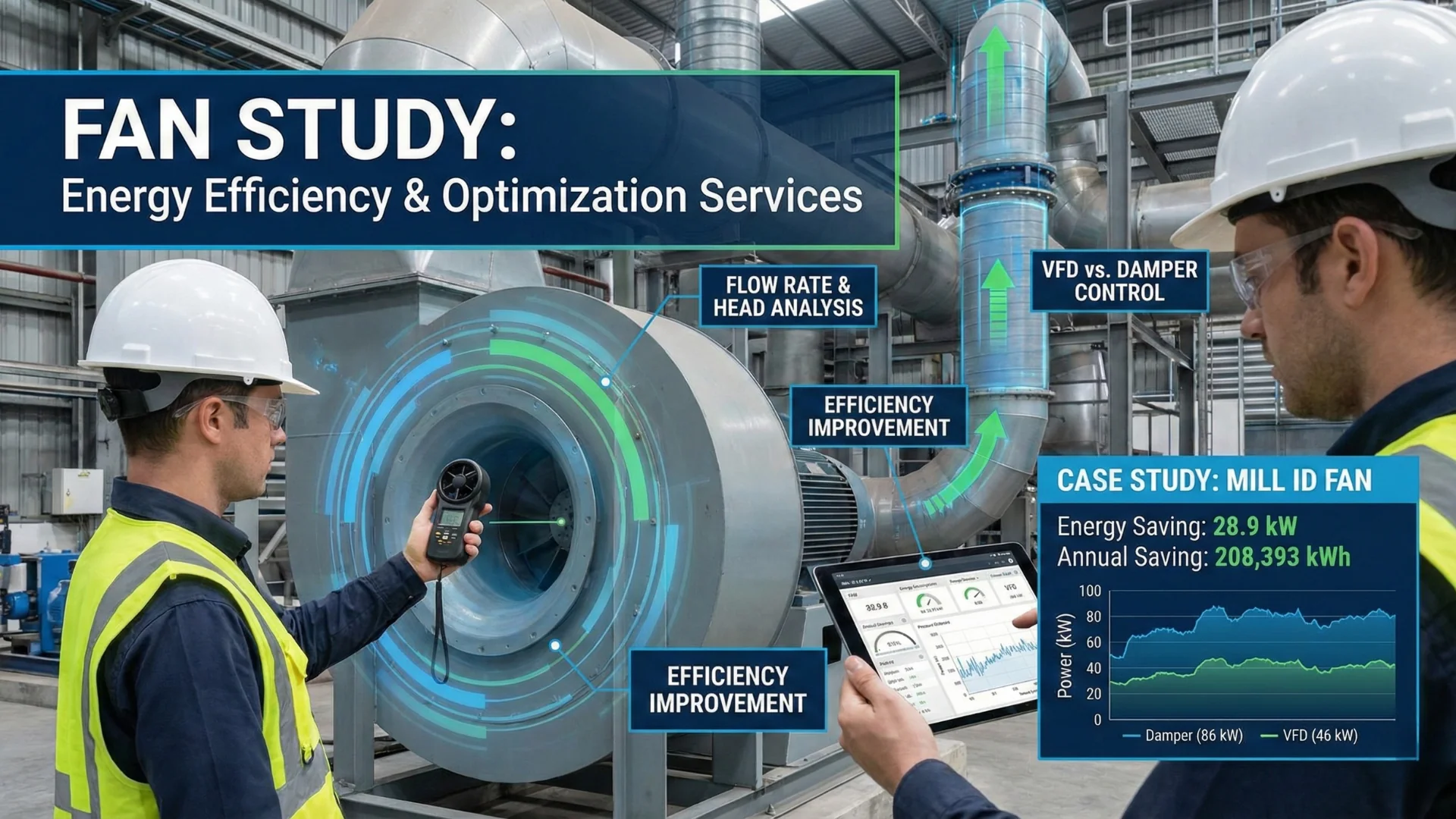

Fan Study

The fans are tested for field performance by measurement of flow, head, temperature on the fan side and electrical motor kW input on the motor side. The air velocity was measured by using anemometer. Multiplication of air velocity with the inlet area gives the air flow.

Carbon Verification Service

We Provide the Carbon Offset Validation Service to the UCR Project. We have validated numerous projects ranging from Wind, Solar, Biomass to Hydro.

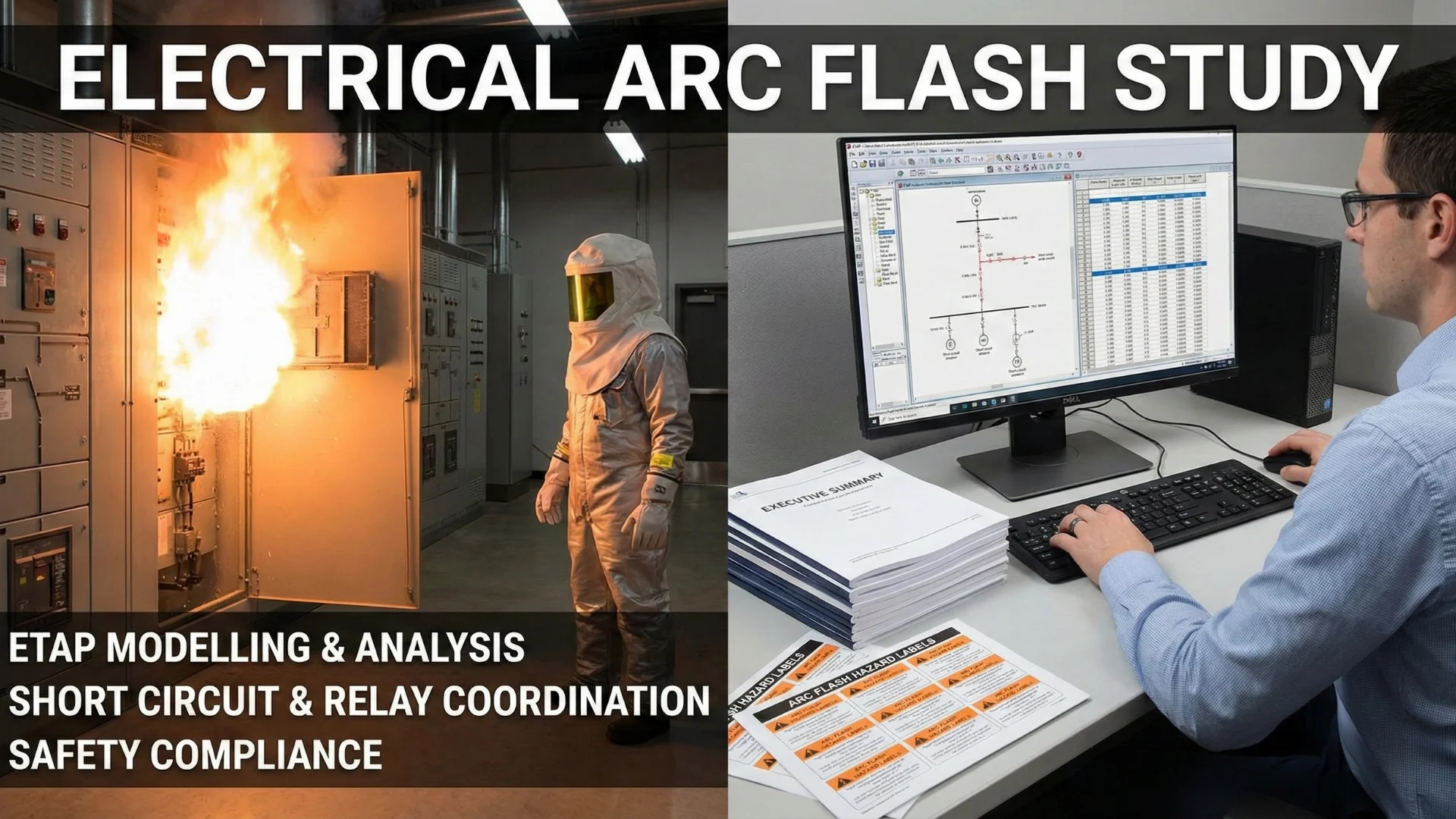

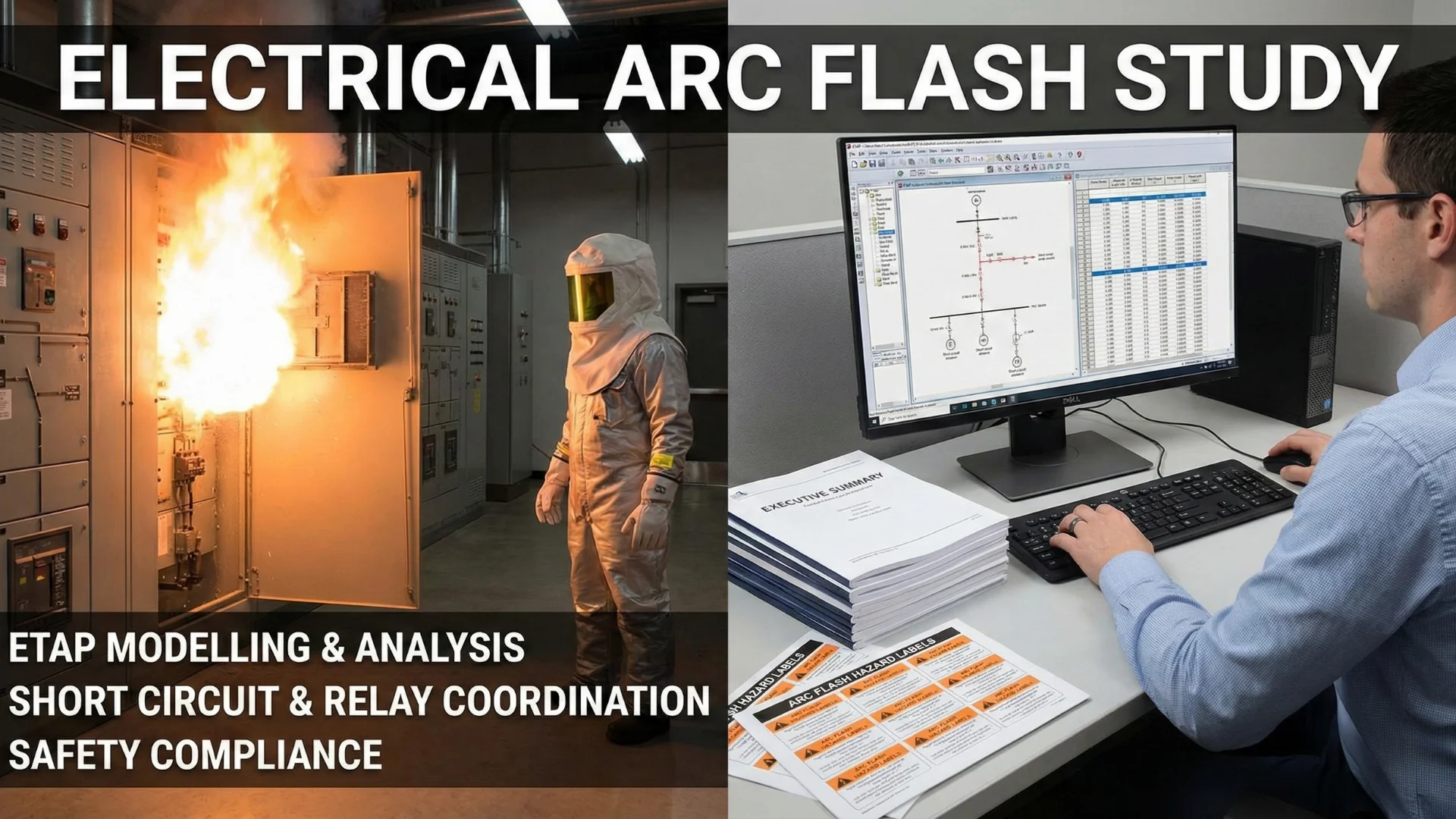

Electrical Arc Flash Study

Comprehensive safety assessment including ETAP Modelling and Short Circuit Studies.

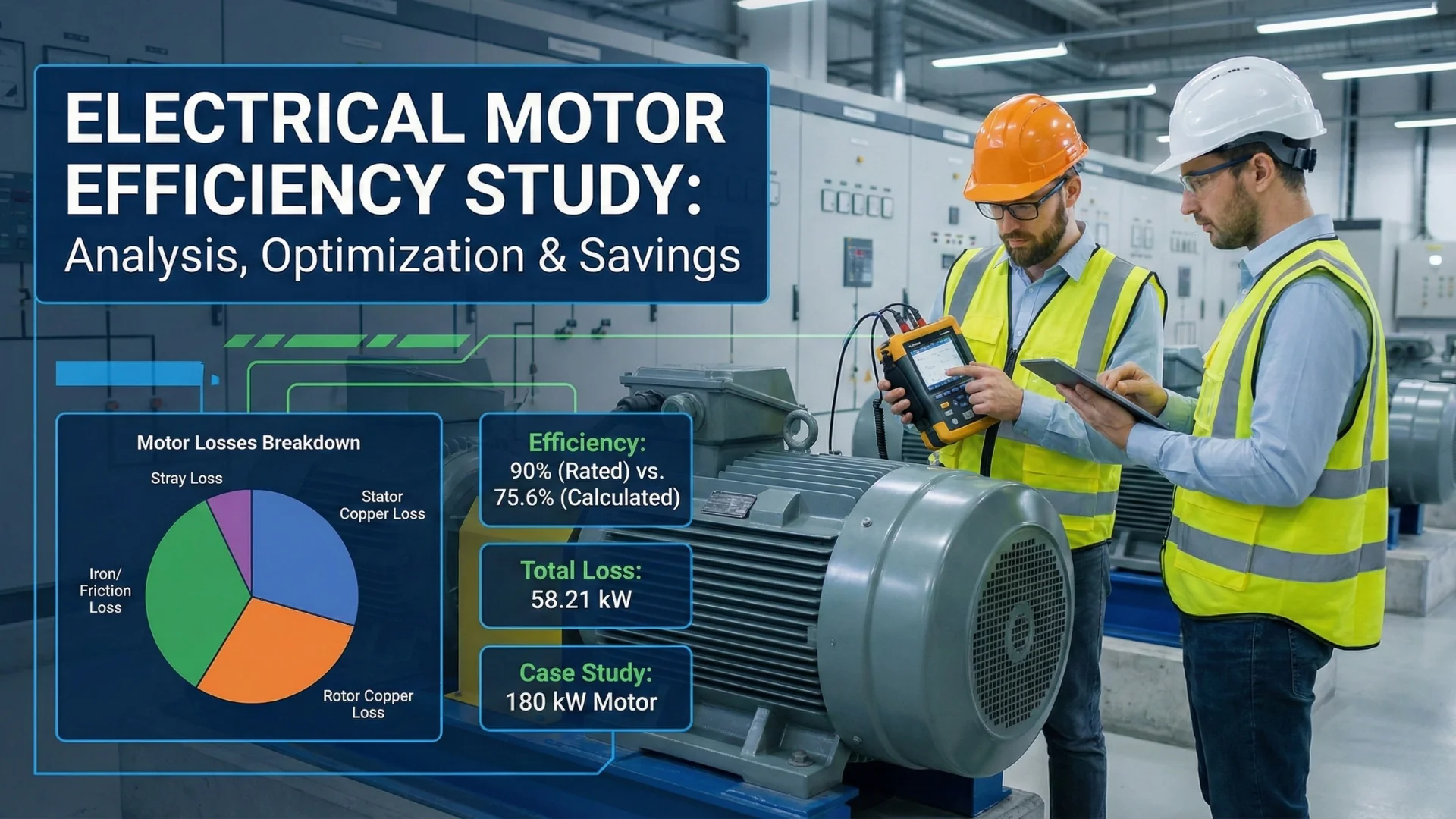

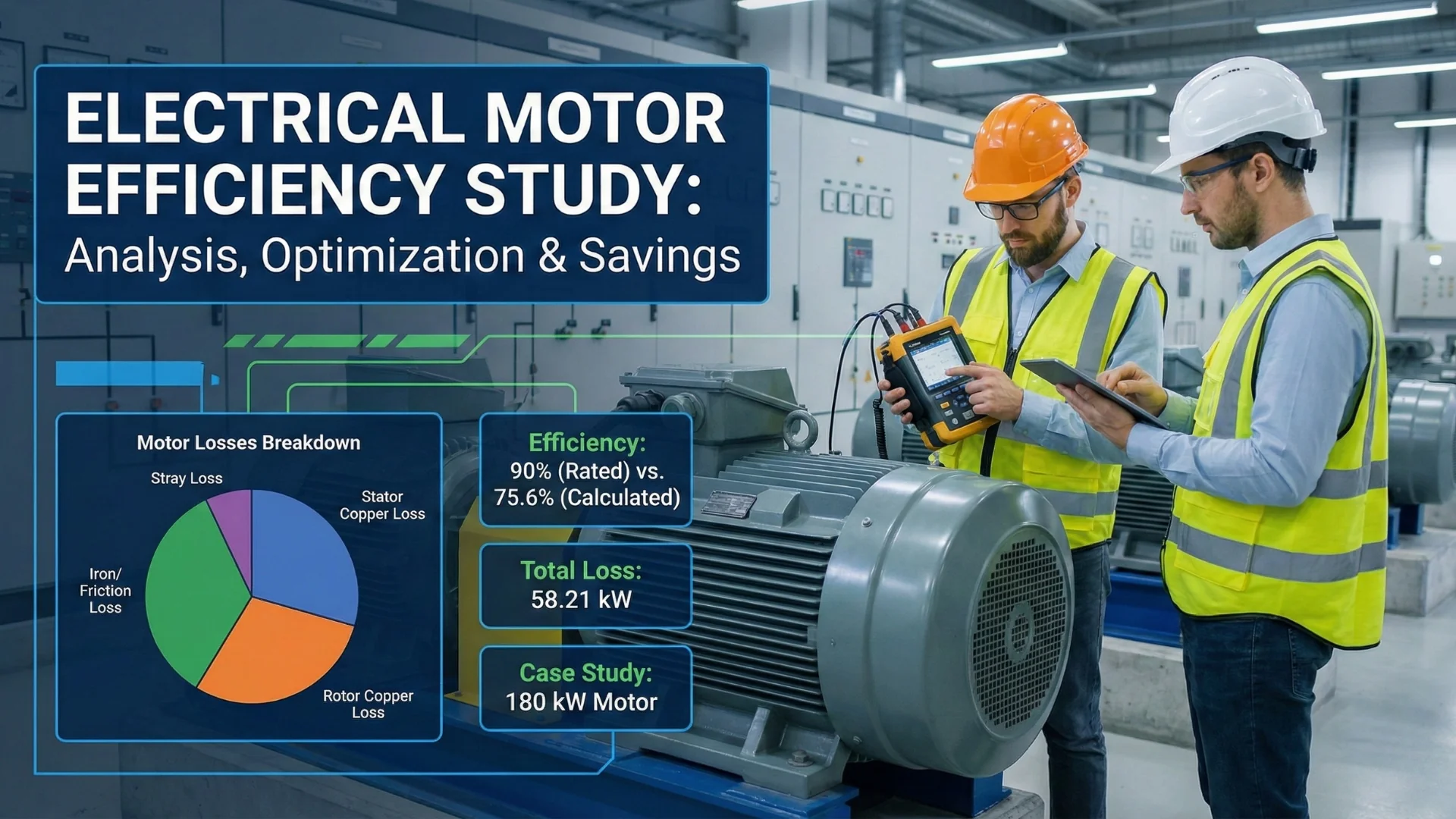

Electrical Motor Efficiency Study

The motor efficiency can be calculated from the total losses, which are assumed to be the summation of the following losses.

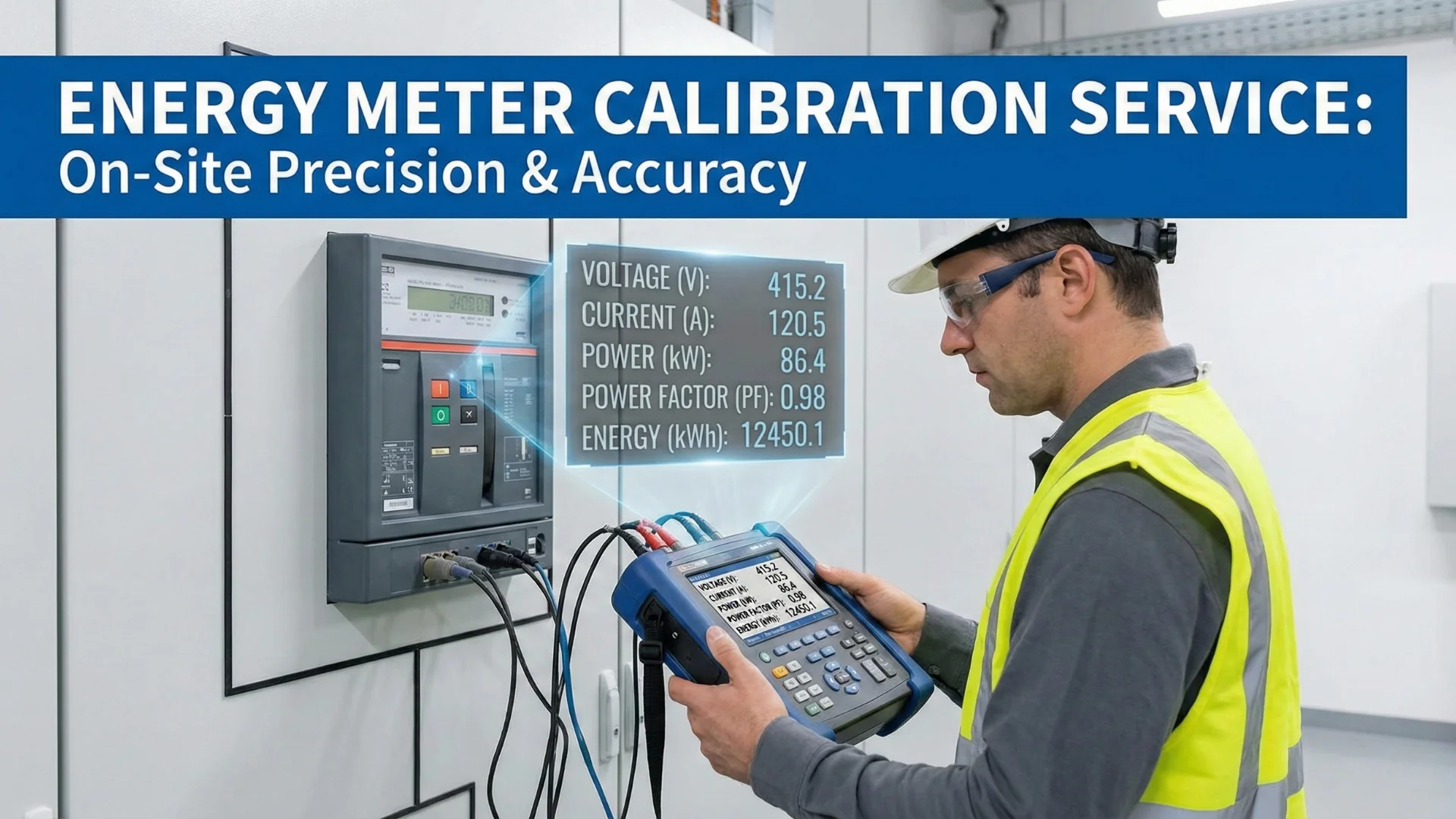

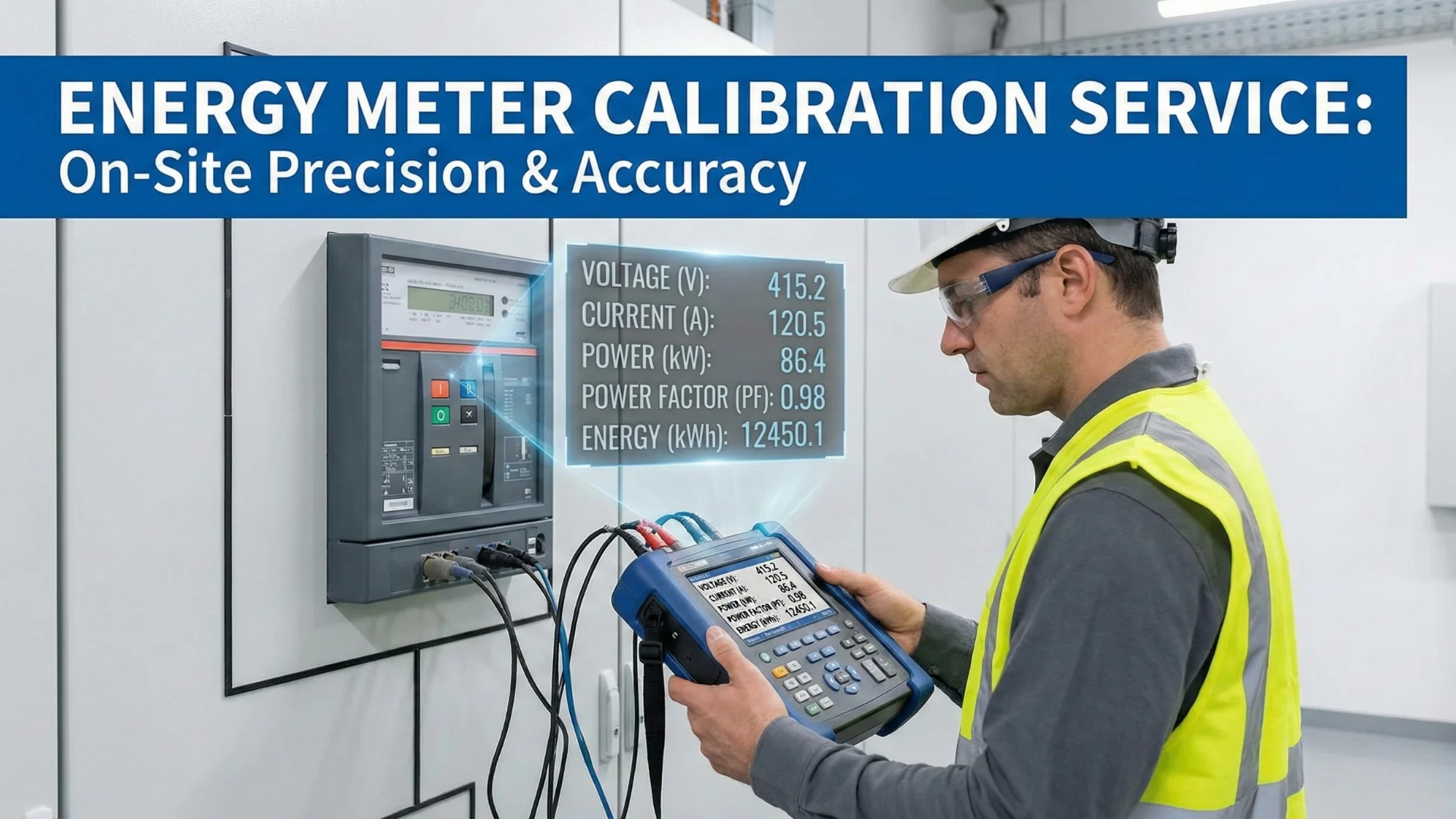

Energy Meter Calibration Service

We provide the Energy Meter Calibration Service at the plant.