Pumping System Study

Overview

All pumps have a characteristic or performance curve that describes the flow rate produced at net or total head. Pump specifications relating head and flow rate correlate to those found on its characteristic curve.

Formulas

Pump hydraulic power and Pump Efficiency can be calculated by the formula:

- Hydraulic Power (kW) = (Flow(Q) * Total Head (Hd – HS) * ρ * g) / 1000

- Pump Efficiency (η) = Hydraulic Power / (Measured Input Power * Motor Efficiency)

Where:

- Q = Water Flow (m3/s)

- Hd = Discharges Head (m)

- Hs = Suction Head (m)

- ρ = Density (Kg/m3)

- g = Gravity (m2/s)

Scope of Work

Overview

- Type of Industry: Chemical, Iron & steel, Textile, Plywood, Pharmaceuticals Etc.

- Application: Cooling Tower Circulation Pump, Water Transfer pump, Chiller Primary & Secondary Pump, Submersible pump, Borewell pump etc.

- Type of Audit: Water pumping Audit

- Energy Conservation Measures: C Section Plant Cooling Circulation Pump: Replace Existing P 235 A Pump with New Energy Efficient Pump

Case Study

| SN | Description | Unit | Value |

|---|---|---|---|

| 1 | Existing Efficiency | % | 37.26 |

| 2 | Proposed efficiency of pump % | % | 82 |

| 3 | Proposed Head | Meter | 30 |

| 4 | Proposed Flow | m3/hr | 400 |

| 5 | Estimated power @ one pump | kW | 42.20 |

| 6 | Standard Motor and Pump Power | kW | 45 |

| 7 | Present norms of pump | kW/m3 | 0.187 |

| 8 | Suggested norms of pump | kW/m3 | 0.105 |

| 9 | Saving in norms | kW/m3 | 0.082 |

| 10 | Saving in kW | kW | 30.268 |

| 11 | Unit cost Rs | Rs./kWh | 6.0 |

| 12 | Daily Operation hour | Hour | 24.000 |

| 13 | Annual operation Day | Day | 330 |

| 14 | Annual Power Saving | kWh | 239723.5 |

| 15 | Saving in monetary terms | Rs. | 1438341.3 |

| 16 | Investment of new Energy Efficient pump | Rs | 290000 |

| 17 | Simple payback period | Month | 2.42 |

You Can Reduce the Carbon Footprint 215 tCo2 by Implementing above Energy Conservation Measures

Proposed New Pump Design

| SN | Description | Unit | Pump 235 A |

|---|---|---|---|

| 1 | Proposed efficiency of pump % | % | 82 |

| 2 | Proposed Head | Meter | 30 |

| 3 | Proposed Flow | m3/hr | 400 |

| 4 | Estimated power @ one pump | kW | 42.20 |

| 5 | Standard Motor and Pump Power | kW | 45 |

Explore Related Services

View All Services →

Energy Audit is defined as “the verification, monitoring and analysis of use of energy including submission of technical report containing recommendations for improving energy efficiency with cost benefit analysis and an action plan to reduce energy consumption”. It builds on the principle "you can't manage what you don't measure". It essentially combines the principles of energy use and statistics.

Energy conservation is the effort made to reduce the consumption of energy by using less of an energy service. This can be achieved either by using energy more efficiently (using less energy for a constant service) or by reducing the amount of service used (for example, by driving less).

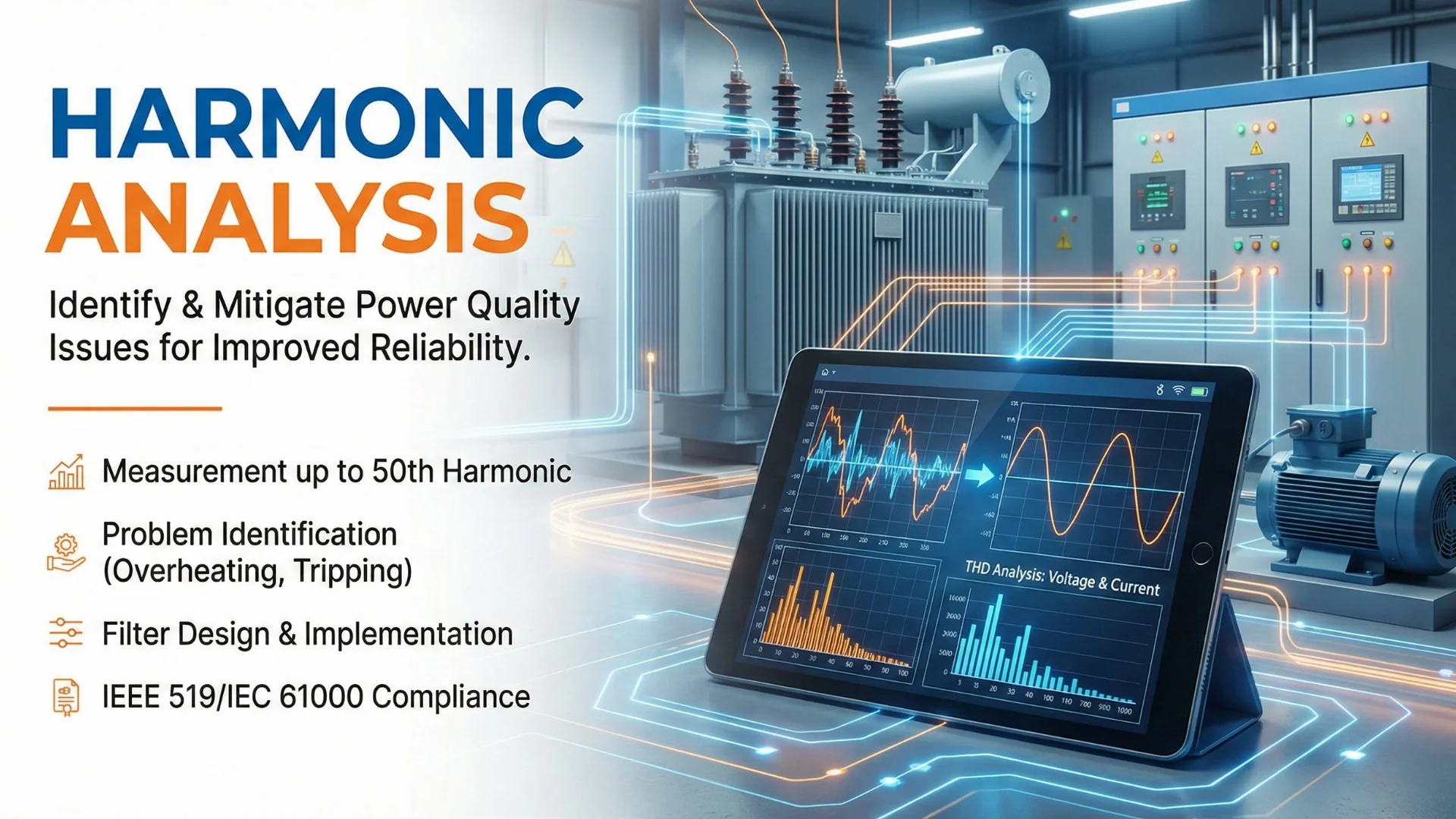

Harmonic analysis is a technique used to study and analyze the harmonic components in a periodic waveform or signal. The main use of harmonic analysis in electrical engineering is to examine the existence and properties of harmonics in electrical power systems. Harmonic voltage or current waveform frequencies are integer multiples of the fundamental frequency. However, due to non-linear loads, such as power electronics, variable speed drives, and certain types of lighting, harmonic currents and voltages can be introduced into the system.

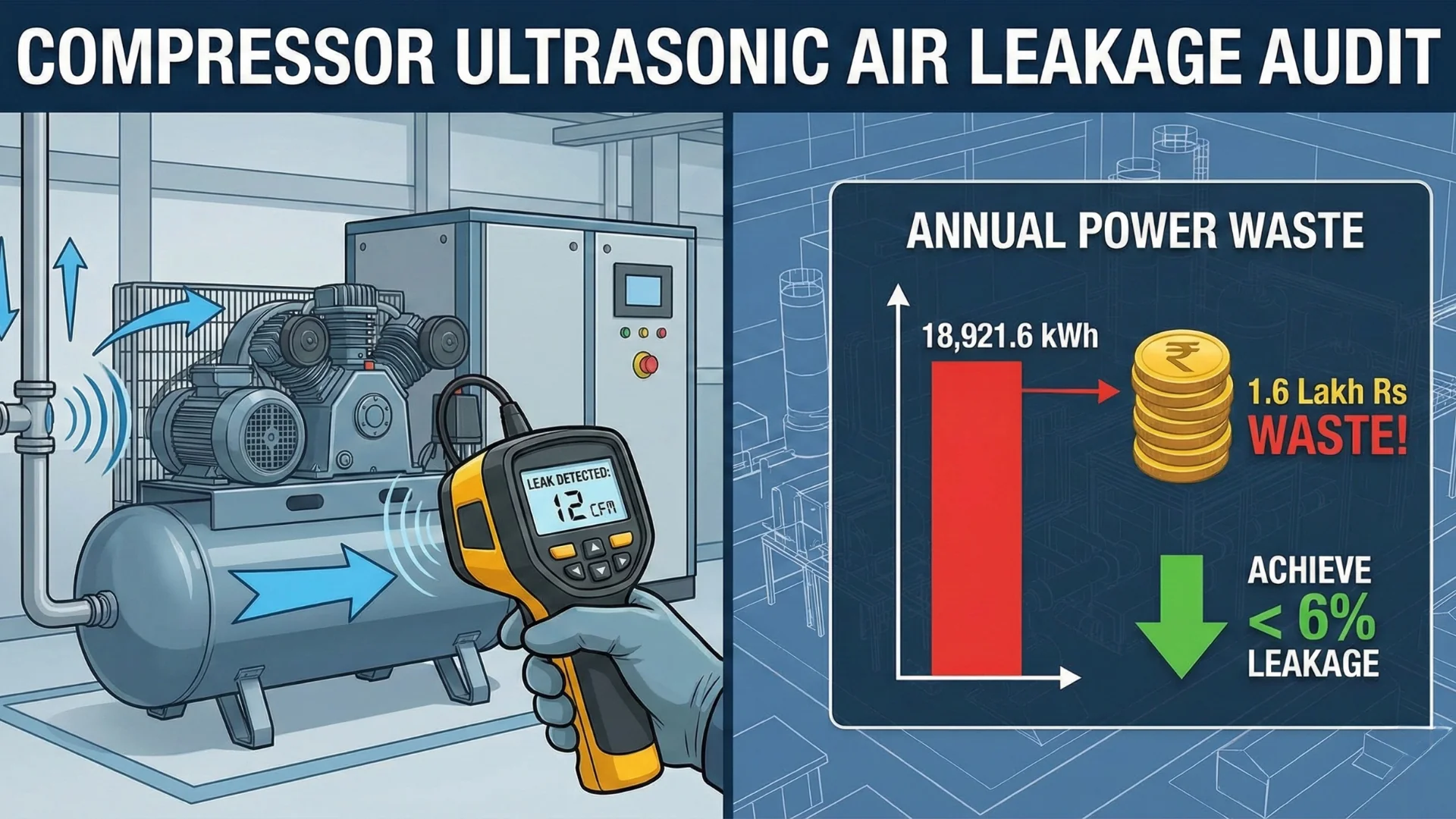

A compressed air audit effectively identifies inefficiencies, reduces energy costs, and improves system performance. Many industrial air compressors operate inefficiently due to leaks, artificial demand, and incorrect air pressure requirements, unnecessarily increasing cost per kWh.