Cooling Tower Study

Overview

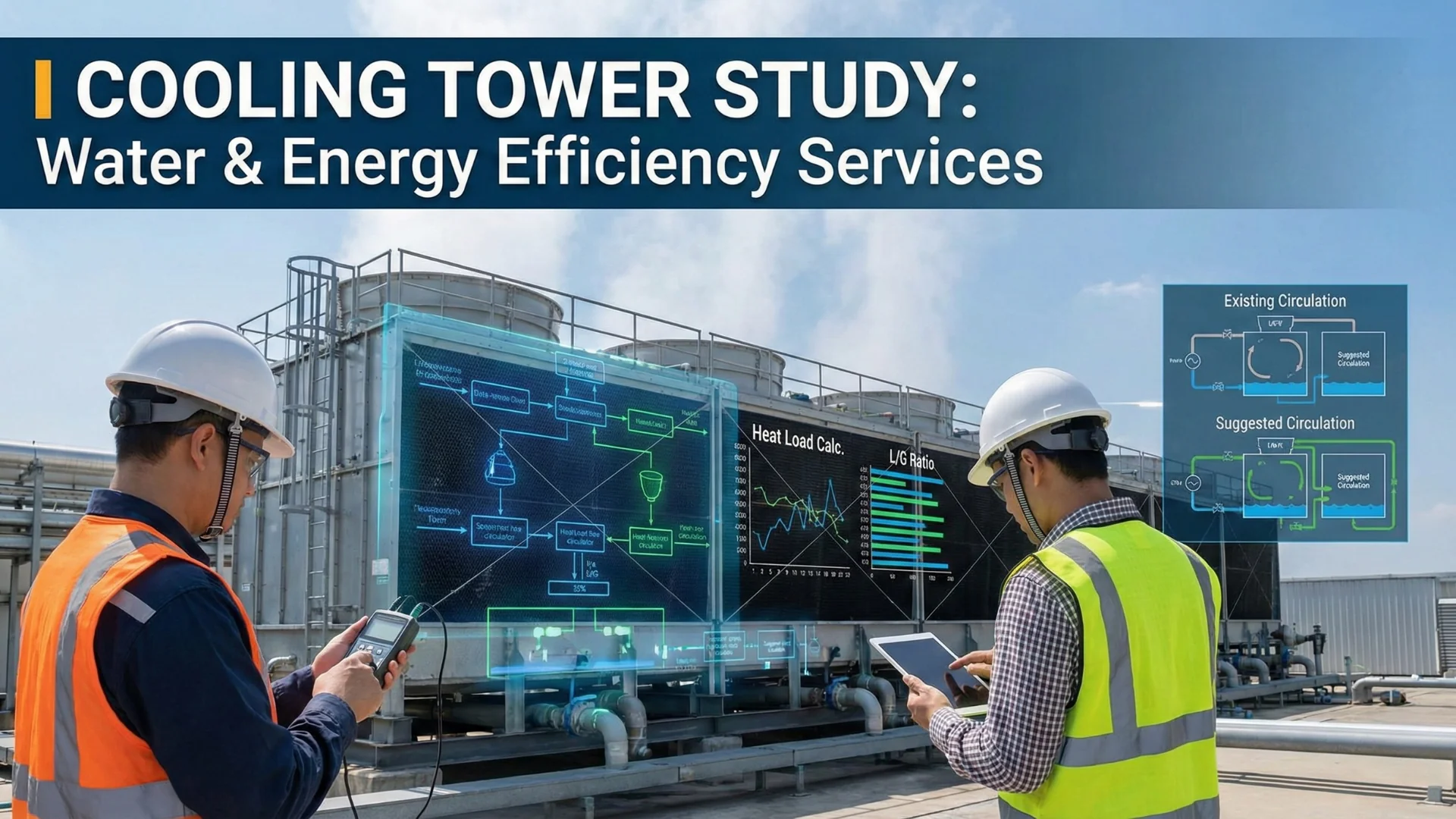

Cooling towers represent largest reuse of water in industrial and commercial applications. Cooling towers offers the means to remove heat from air conditioning systems and industrial processes generating excess heat. Cooling towers are normally designed for maximum process load and worst ambient conditions. Optimizing operation and effective maintenance of cooling towers systems offer facility and process managers significant savings in energy and water consumption. As result saving potential of about 20-25% can be achieved by optimizing excess capacities of pumps and fans catering to under loaded process.

Most cooling towers develop significant draft. Drift eliminator at the top of tower prevent water from being blown off or sucked out of tower. This type of water loss is called drift loss or windage loss. Makeup water is added to replenish the water lost by evaporation or blow-down.

Liquid/Gas (L/G) ratio, of a cooling tower is the ratio between the water and the air mass flow rates. Against design values, seasonal variations require adjustment and tuning of water and air flow rates to get the best cooling tower effectiveness through measures like water box loading changes, blade angle adjustments.

Scope of Work

Case Study

Energy Conservation Measures : Stop the Hotwell Circulation Pump by Eliminating the Hotwell Section

Observation

Suggestion

Data

| SN | Description | Unit | Data |

|---|---|---|---|

| 1 | Hot Well Circulation Pump 1 Power | kW | 5.551 |

| 2 | Hot Well Circulation Pump 1 Power | kW | 5.103 |

| 3 | Hot Well Circulation Pump 1 Power | kW | 5.056 |

| 4 | Total Power Consumption | kW | 15.709 |

| 5 | Total Running Day | Day | 300.00 |

| 6 | Electrical Unit Cost | Rs/ kWh | 8.30 |

| 7 | Annual Power Saving Possible | kWh | 113105 |

| 8 | Annual Saving in Monetary Terms | Rs/- | 938776 |

| 9 | Investment of Merge Hotwell and Cold Well Section | Rs/- | 100000 |

| 10 | Simple Payback Period | Month | 1.28 |

Existing Circulation of Water at Cooling Tower

Existing Circulation of Water at Cooling Tower

Suggested Cooling Tower Water Circulation

Suggested Cooling Tower Water Circulation

Energy Saving Opportunities in Cooling Tower

Explore Related Services

View All Services →

Energy Audit is defined as “the verification, monitoring and analysis of use of energy including submission of technical report containing recommendations for improving energy efficiency with cost benefit analysis and an action plan to reduce energy consumption”. It builds on the principle "you can't manage what you don't measure". It essentially combines the principles of energy use and statistics.

Energy conservation is the effort made to reduce the consumption of energy by using less of an energy service. This can be achieved either by using energy more efficiently (using less energy for a constant service) or by reducing the amount of service used (for example, by driving less).

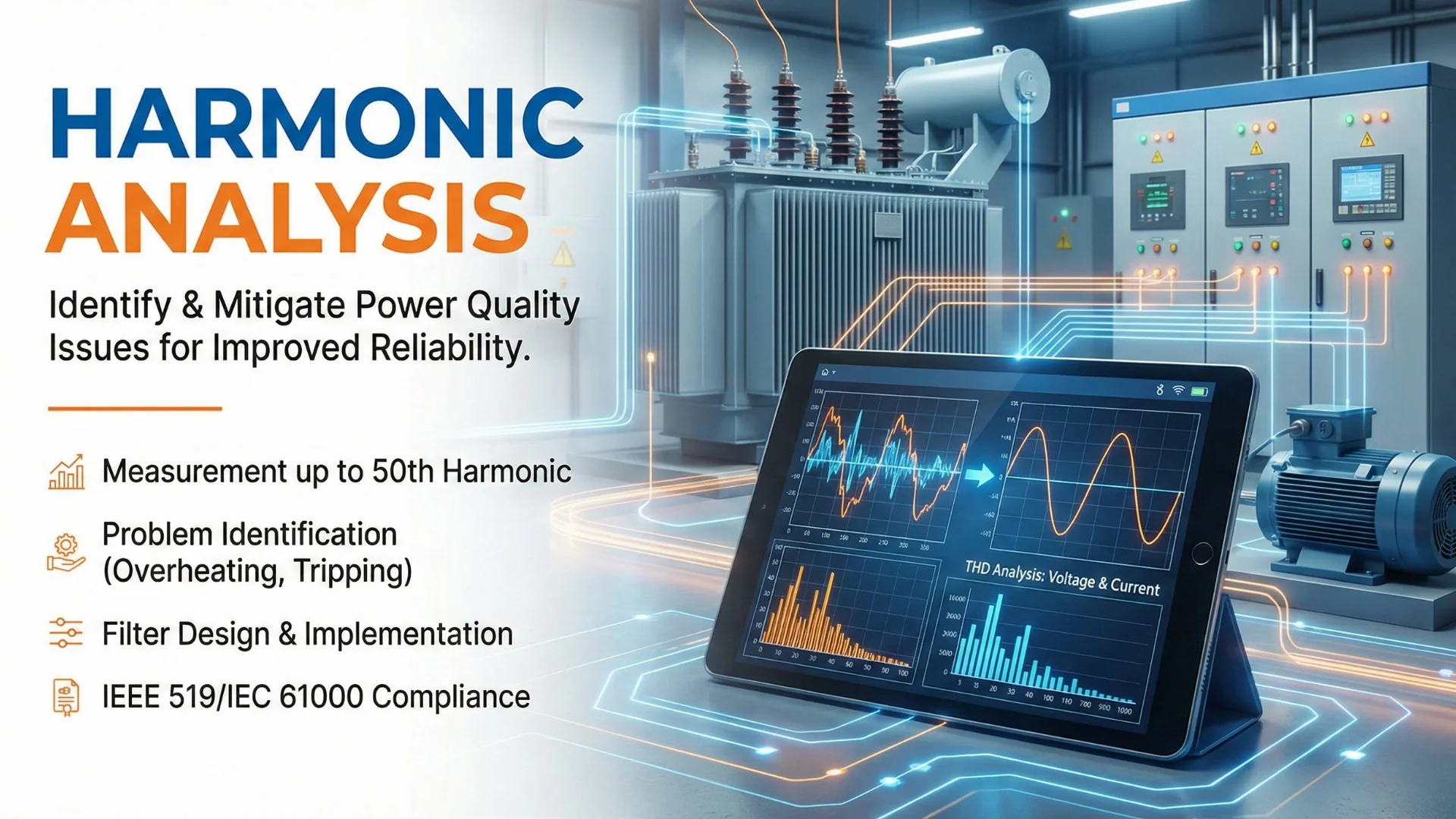

Harmonic analysis is a technique used to study and analyze the harmonic components in a periodic waveform or signal. The main use of harmonic analysis in electrical engineering is to examine the existence and properties of harmonics in electrical power systems. Harmonic voltage or current waveform frequencies are integer multiples of the fundamental frequency. However, due to non-linear loads, such as power electronics, variable speed drives, and certain types of lighting, harmonic currents and voltages can be introduced into the system.

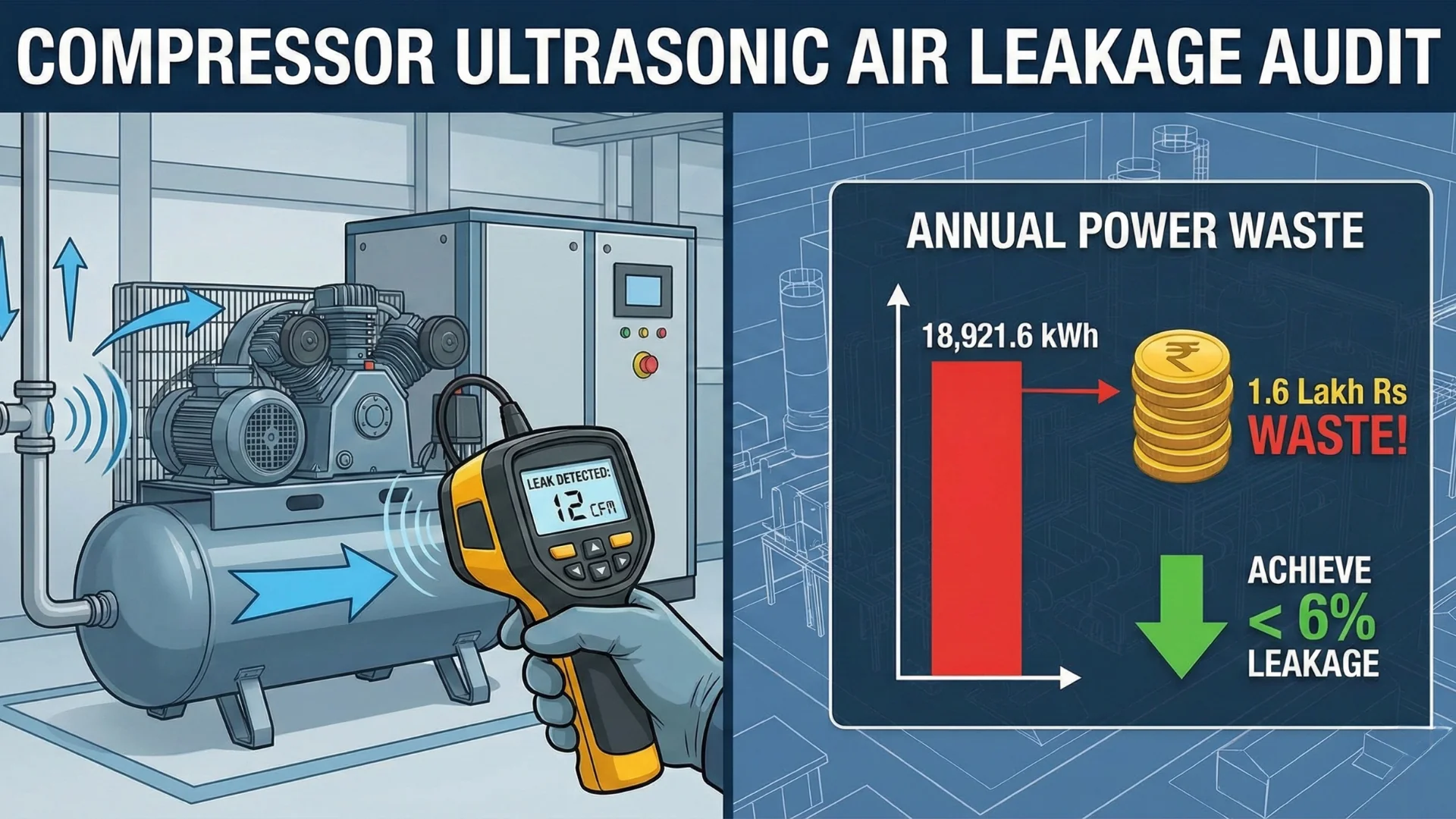

A compressed air audit effectively identifies inefficiencies, reduces energy costs, and improves system performance. Many industrial air compressors operate inefficiently due to leaks, artificial demand, and incorrect air pressure requirements, unnecessarily increasing cost per kWh.