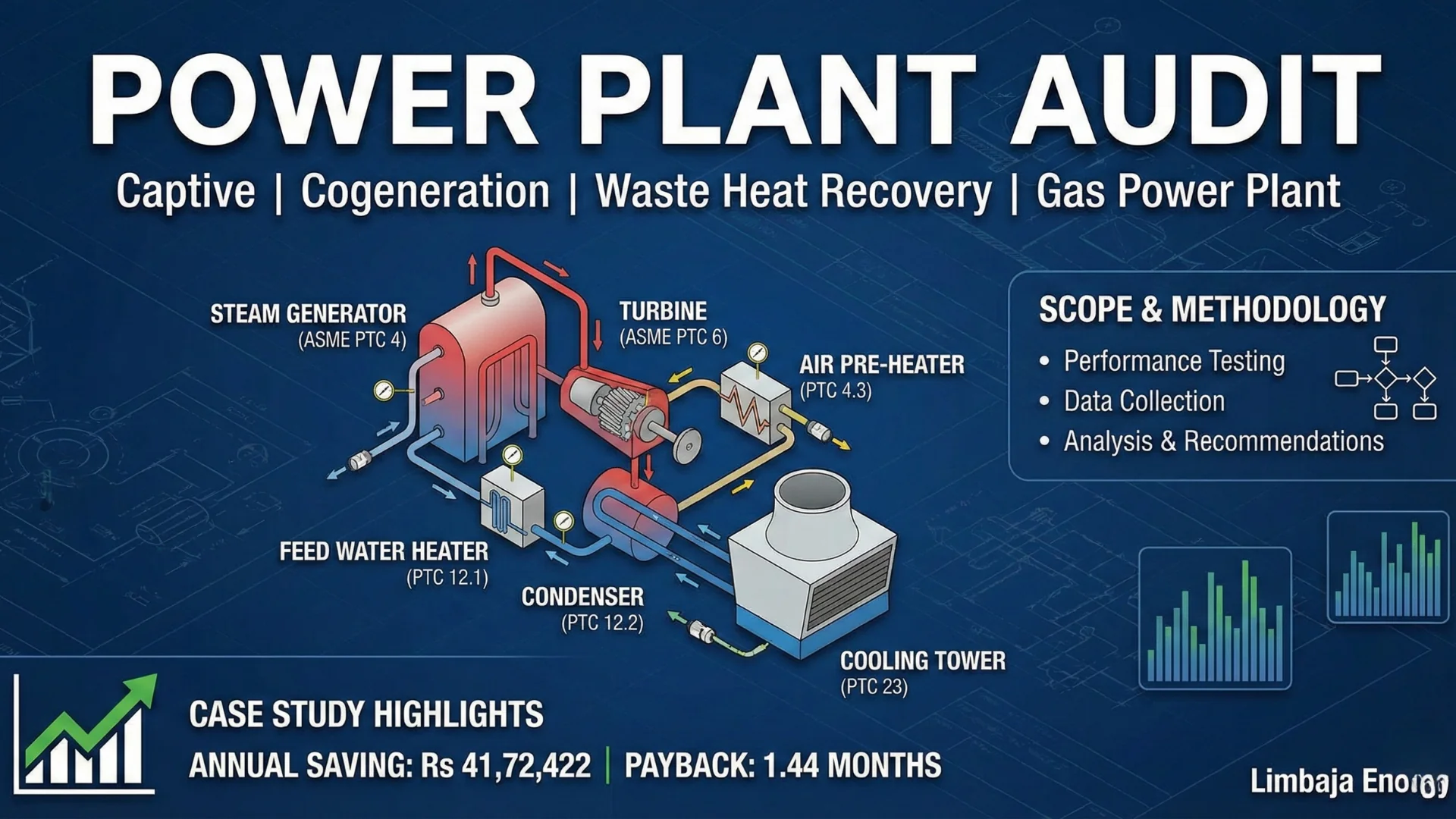

Power Plant Audit

Overview

Performance testing of Captive, Cogen, Waste Heat Recovery, and Gas Power Plants in accordance with respective ASME PTC Codes.

Type of Plant

Scope of Work for Power Plant Audit

Methodology

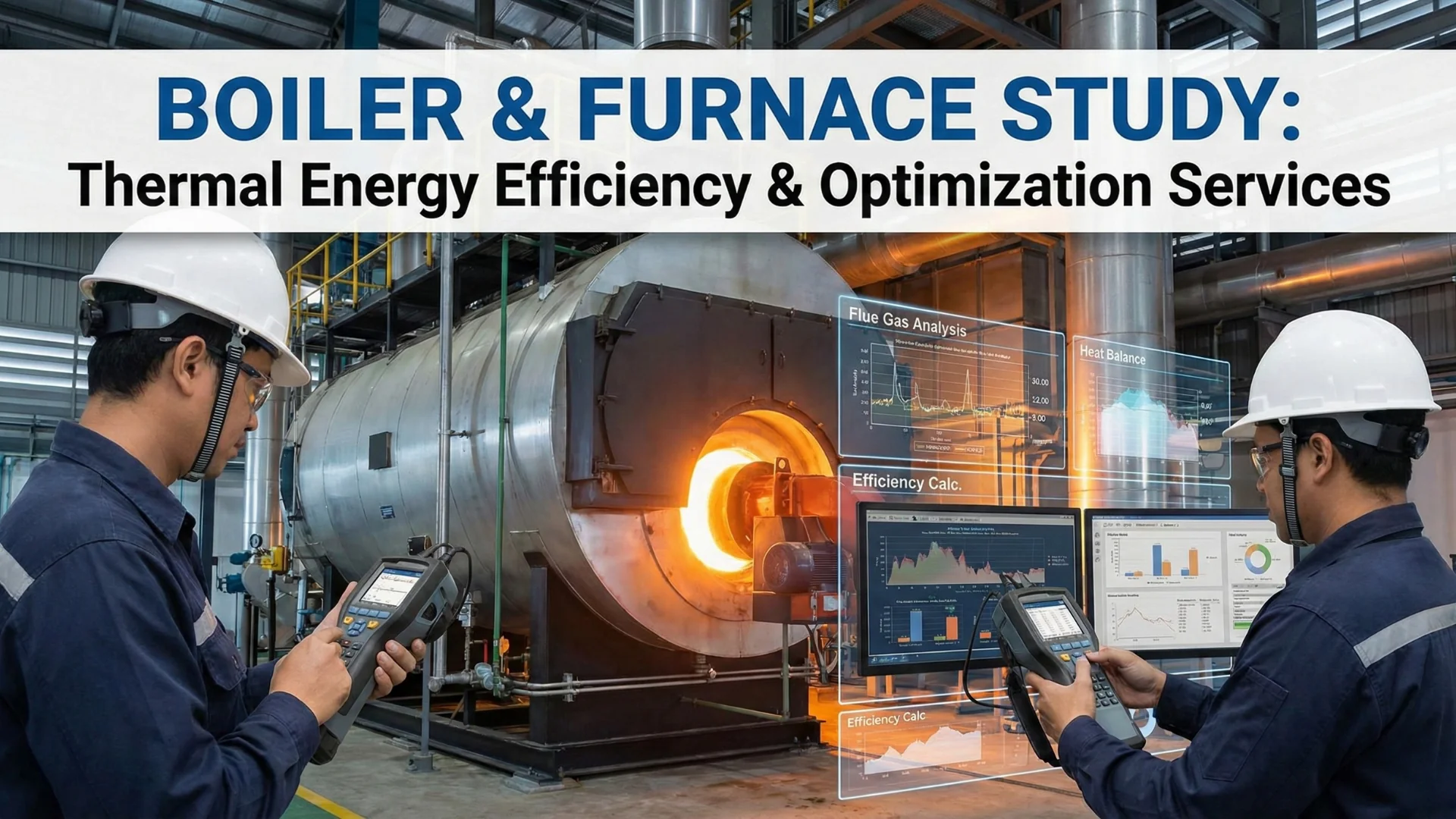

Steam Generator Boiler Efficiency Evaluation by indirect method by (ASME PTC 4 -2008)

Objective: Determine major loss Covered Are:

Effectiveness of Air Pre heater & Ingress identification (PTC 4.3)

Turbine (ASME PTC 6 -2004)

HP – LP Feed Water heater (ASME PTC 12.1)

- Performance Study of HP-LP Heaters

Condenser (ASME PTC 12.2)

- Condenser performance with reference to Cooling Water flow and temperature of circulating water

- Study of Deviation/Deterioration in the performance of condenser

- Deviation in performance due to circulation water flow

- Deviating due to scale formation

- Cooling water pressure loss across condenser

- Required Parameter Condensate Flow to deaerator

- Condenser back pressure, CW inlet and outlet temperature, CW Flow will be measured using portable flow meter.

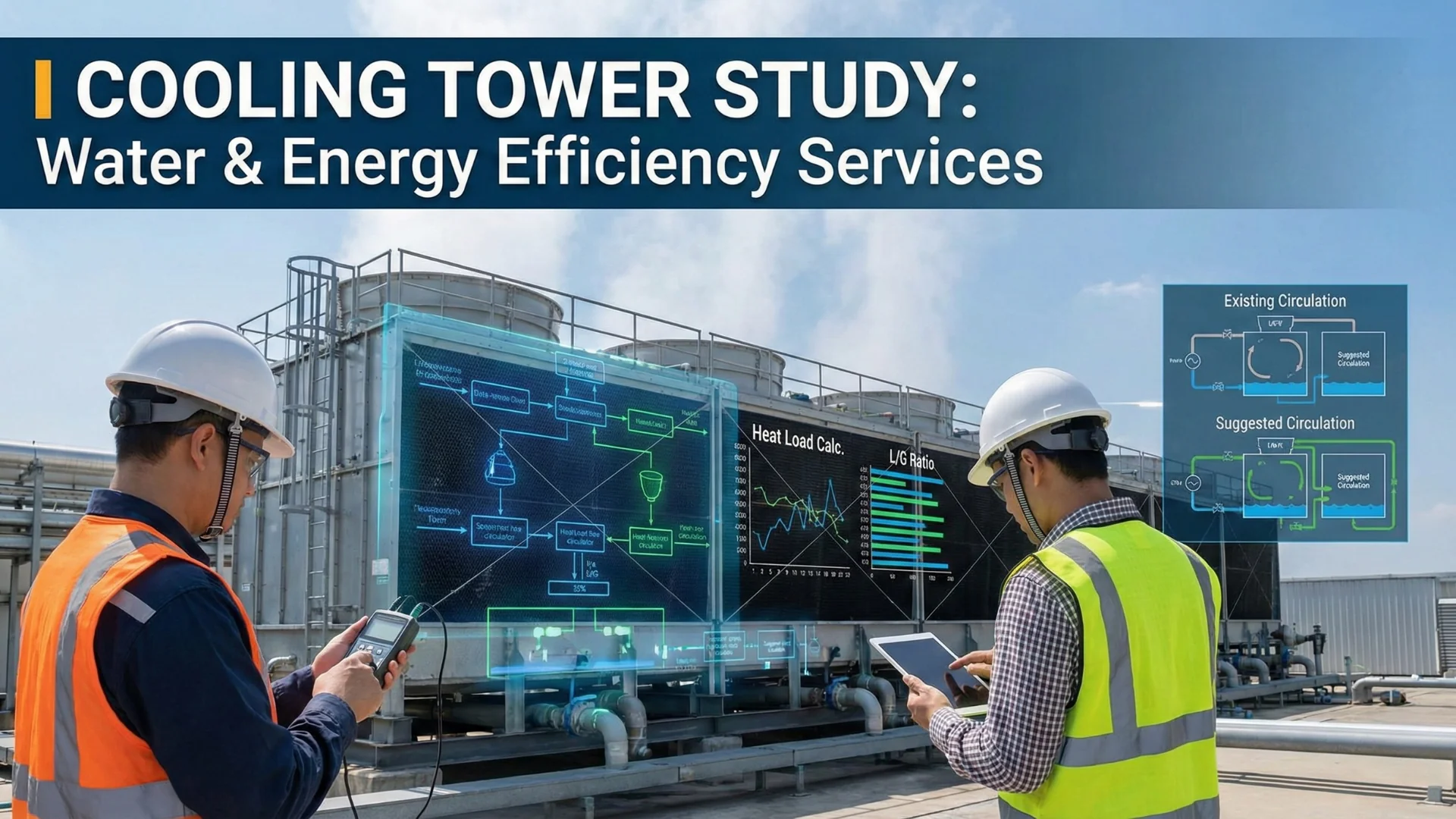

Cooling Tower (PTC 23)

- Assessment of cooling tower capacity and efficiency/effectiveness

- Assessment of condenser heat load

- DBT, WBT air velocity and humidity CW Temperature shall be measured

Coal Analysis

- Ultimate and Proximate Analysis of Coal

- GCV Test of APH Ash, ESP Ash Economizer Ash and Bed Bottom Ash

Overview

- Energy Conservation Measure : Use LP Heater Steam Line for Heating the Boiler Feed Water and Increase the Turbine Power.

Case Study

| SN | Parameter | Unit | Value |

|---|---|---|---|

| 1 | Power Generation Per day Without LP Heater Running | MWD | 347.86 |

| 2 | Power Generation Per day With LP Heater Running | MWD | 351.05 |

| 3 | Power Saving Per day | MWD | 3.20 |

| 4 | Annual Operation Hours | Day | 300.00 |

| 5 | Annual Power Saving | MW | 959.11 |

| 6 | Electricity Unit Cost | Rs/kWh | 4.35 |

| 7 | Annual Saving in Monetary Terms | Rs/- | 41,72,422 |

| 8 | Investment | Rs/- | 5,00,000 |

| 9 | Simple Payback Period | Month | 1.44 |

Overview

- Comparison of LP Heater Steam Line Off Condition and On Condition.

Case Study

| SN | Parameter | Unit | LP Heater Steam Line Not Working Condition | LP Heater Steam line Working Condition |

|---|---|---|---|---|

| 1 | Extraction 1st stage flow Turbine Inlet | TPD | 1397 | 1397 |

| 2 | Extraction 1st stage flow Turbine Outlet | TPD | 44.88 | 0 |

| 3 | Extraction 2nd stage flow Turbine Outlet | 0 | 57.6 | |

| 4 | Condensing Stage flow | TPD | 1352.12 | 1339.4 |

| 5 | Extraction 1st stage Enthalpy inlet | kcal/kg | 805.4 | 805.4 |

| 6 | Extraction 1st stage Enthalpy outlet | kcal/kg | 717.010 | 717.01 |

| 7 | Extraction 2nd stage Enthalpy inlet | kcal/kg | 0 | 717.01 |

| 8 | Extraction 2nd stage Enthalpy outlet | kcal/kg | 0.000 | 633.13 |

| 9 | Extraction Condensing stage Enthalpy inlet | kcal/kg | 717.01 | 633.13 |

| 10 | Extraction Condensing stage Enthalpy outlet | kcal/kg | 570.000 | 570 |

| 11 | Extraction 1st stage Power Generation | MWD | 143.5 | 0 |

| 12 | Extraction 2nd Stage Power Generation | MWD | 0.0 | 279.84 |

| 13 | Extraction Condensing Stage Power Generation | MWD | 231.13 | 98.32 |

| 14 | Total Power Generation | MWD | 374.72 | 378.16 |

| 15 | Turbine Generator Efficiency | % | 96 | 96 |

| 16 | Gear Box Efficiency | % | 97 | 97 |

| 17 | Calculated Power Output Power Generation | MWD | 347.86 | 351.05 |

| 18 | More Power Generation | MWD | 3.20 |

Explore Related Services

View All Services →

Energy Audit is defined as “the verification, monitoring and analysis of use of energy including submission of technical report containing recommendations for improving energy efficiency with cost benefit analysis and an action plan to reduce energy consumption”. It builds on the principle "you can't manage what you don't measure". It essentially combines the principles of energy use and statistics.

Energy conservation is the effort made to reduce the consumption of energy by using less of an energy service. This can be achieved either by using energy more efficiently (using less energy for a constant service) or by reducing the amount of service used (for example, by driving less).

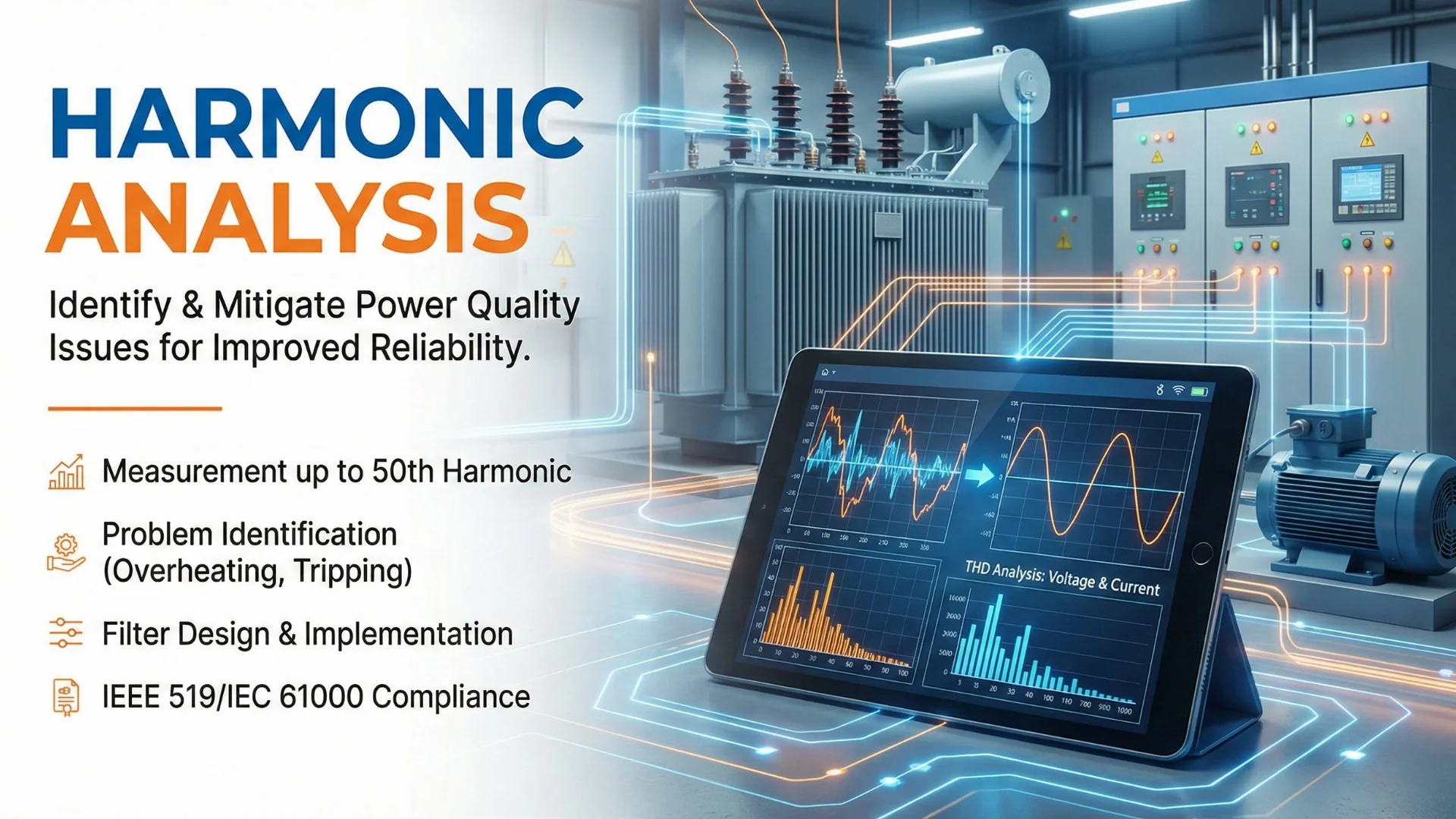

Harmonic analysis is a technique used to study and analyze the harmonic components in a periodic waveform or signal. The main use of harmonic analysis in electrical engineering is to examine the existence and properties of harmonics in electrical power systems. Harmonic voltage or current waveform frequencies are integer multiples of the fundamental frequency. However, due to non-linear loads, such as power electronics, variable speed drives, and certain types of lighting, harmonic currents and voltages can be introduced into the system.

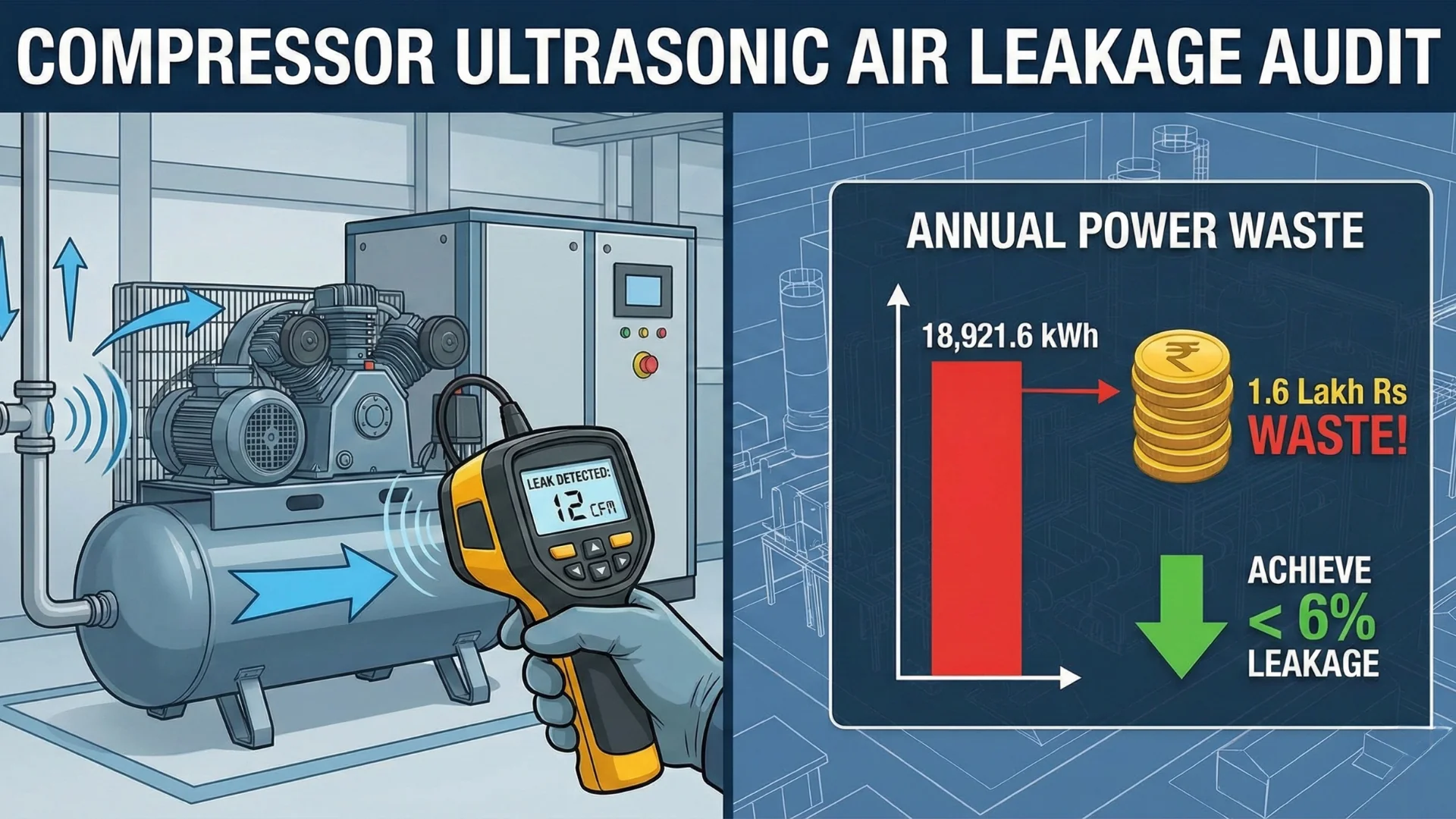

A compressed air audit effectively identifies inefficiencies, reduces energy costs, and improves system performance. Many industrial air compressors operate inefficiently due to leaks, artificial demand, and incorrect air pressure requirements, unnecessarily increasing cost per kWh.